-

ABOUT HCHC

-

Product Center

Product

- HC internal gear pump

- CBRHA Gear pump

- CBRH Gear pump

- CBWS/F-D3 gear pump

- CBW/FB-E3 gear pump

- CBXZ-C compound gear pump

- CBWKGY gear pump

- CBGT4 gear pump

- CBF-F5 gear pump

- CBGTGC Multi-gear oil pump

- CBVH Triple gear pump

- CBKP Triple gear pump

- CBKL-G/G double gear oil pump

- CBHYG-G/F double gear oil pump

- CBHY-G/F double gear oil pump

- CBV2/2 double gear oil pump

- CBGTFL double gear oil pump

- CBKP Double gear oil pump

- CBG2/2 Double gear oil pump

- CBGTBLT Double gear oil pump

- CBGTBLA2 Double gear oil pump

- CBTLZTD-F/F Double gear oil pump

- CBTLZTA-F/F Double gear oil pump

- CBGNL Double gear oil pump

- CBNL-F5/F5 Double gear oil pump

- CBHLB-F5/F5 Double gear oil pump

- CBHLD-F5/F5 Double gear oil pump

- CBQTF Double gear oil pump

- CBQT-*5/F4 Double gear oil pump

- CBQL-*5/F5 Double gear oil pump

- CBTL-*4/*4 Double gear oil pump

- CBWL-*3/*3 CBKL-G/G

- CBKP gear pump

- CBV gear pump

- CBGTG

- CBGTF2 Gear pump

- CBZTG3 Gear pump

- CBZTG2 Gear pump

- CBGTC2 gear pump

- CBGTB2 Gear pump

- CBZTC2 Gear pump

- CBTZTD Gear pump

- CBTZTA-F Gear pump

- CBGX Gear pump

- CBNZQ -F5 Gear pump

- CBN-F5 Gear pump

- CBWma-F,CBWmb-F Gear pump

- CBW-F2 Gear pump

- CBG2 Gear pump

- CBF-F6 Gear pump

- CBQ-*5 Gear pump

- CBHB-F5 gear pump

- CBH-*5 Gear pump

- CBF-*4 Gear pump

- CBWKA-F3 Gear pump

- CBHZA-F gear pump

- CBHZ-F Gear pump

- CBHE Gear pump

- CBHV Gear pump

- CBHV Gear pump(rear inlet and outlet)

- CBHC Gear pump

- CBKEC Gear pump

- CBTD-F4 Gear pump

- CBT-F4 Gear pump

- EYF*-15Multiway valve

- HCZTF-120 Multi-way valve

- DYCDBF*-15Multiway valve

- DCFB-G60L-4 Solenoid Valve

- DCF*-50 Solenoid Valve

- XSFα* speed limiting valves

- 1WFL* Shunt valve

- SDV*-70 multi-way valves

- SDVA*-40 Multi-way valves

- SDV*-40

- SDV*-25

- ZDaG*-15 Multi-way valves

- ZDG*-15 Multi-way valves

- ZD*-10 Integral multi-way valves

- BDL*-40

- FP6G*-15

- EDL*-25 Multiway valve

- EDL*-20 Multi-way valves

- EDL*-15 Multi-way valve

- EDL*-10 Multi-way valves

- ZL*-20 Multi-way valves

- DLSG*-20 Multiway valve

- DLS*-20 Multi-way valves

- DLS*-15 Multiway valve

- DF28-15 Multiway valve

- DF*-15 Multi-way valves

- DL*-20 Multi-way valves

- DL*-15 Multi-way valves

- DYDLa*-20 Multi-way valve

- DYDLa*-15 Multi-way valve

- HCZF*-15

- OBV*/HXQ*

- YCDC*-20 Multiple directional valve

- YCDB*-20 Multiple directional valve

- CDB*-20 Multiple directional valve

- YCDC*-15

- YCDB*-15 Multiple directional valve

- DCDB*-15 Multiway valve

- CDB* -15 Multiway valve

-

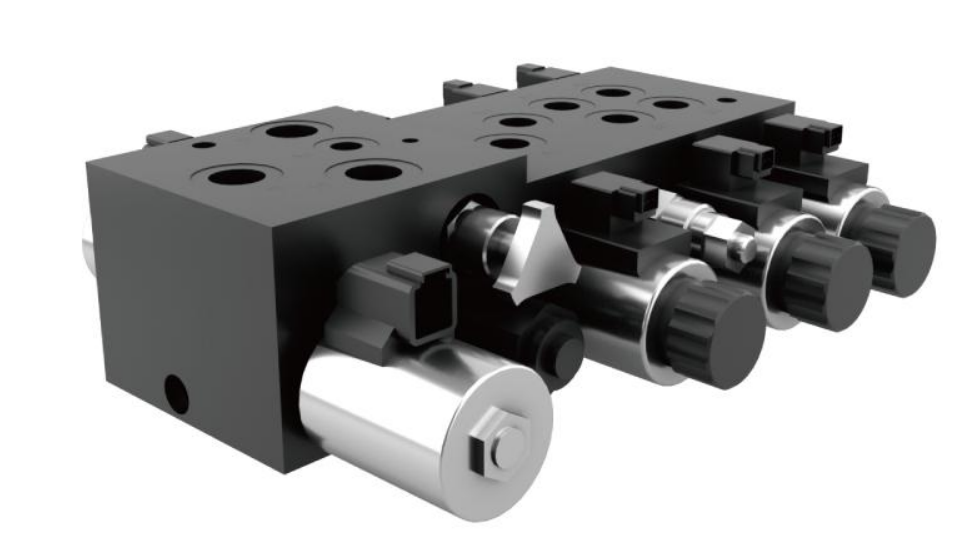

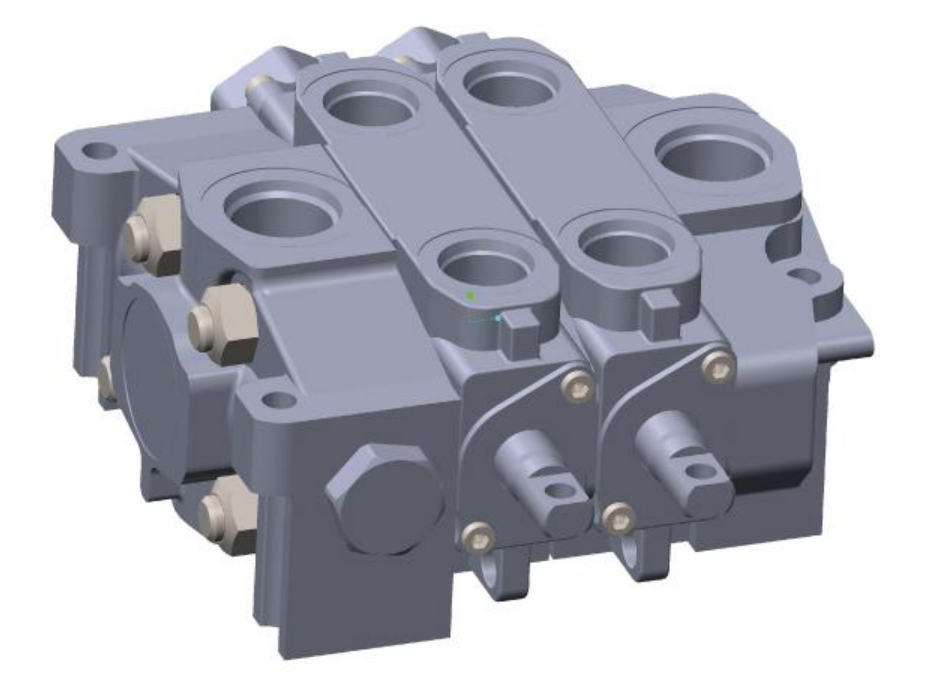

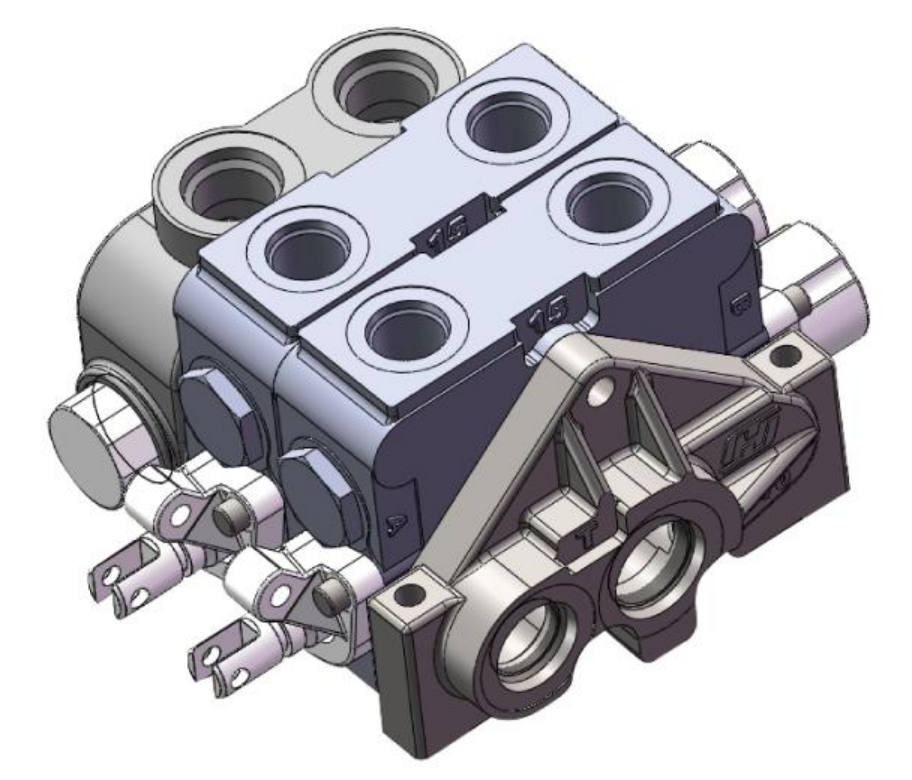

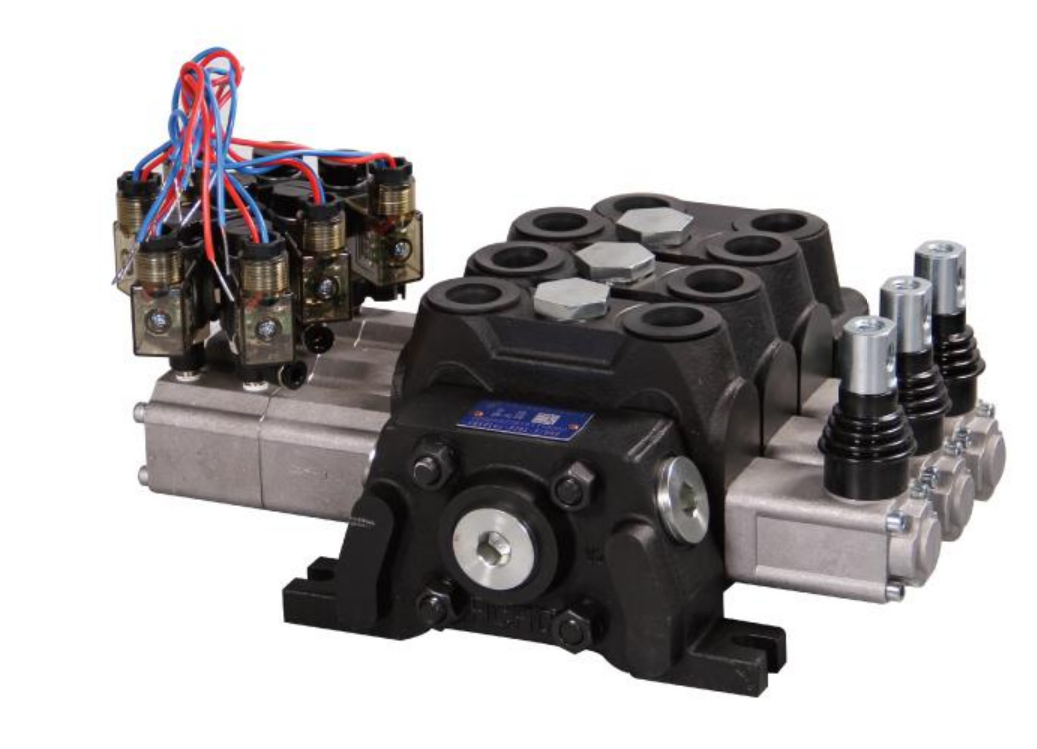

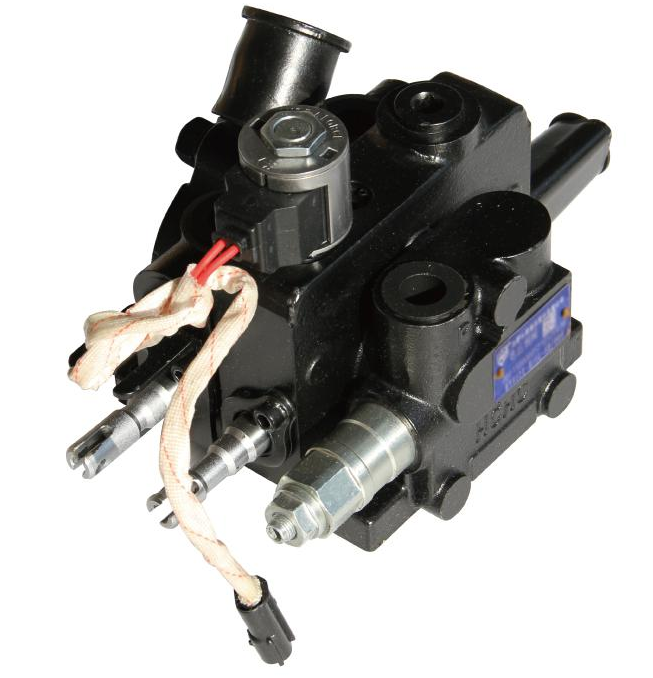

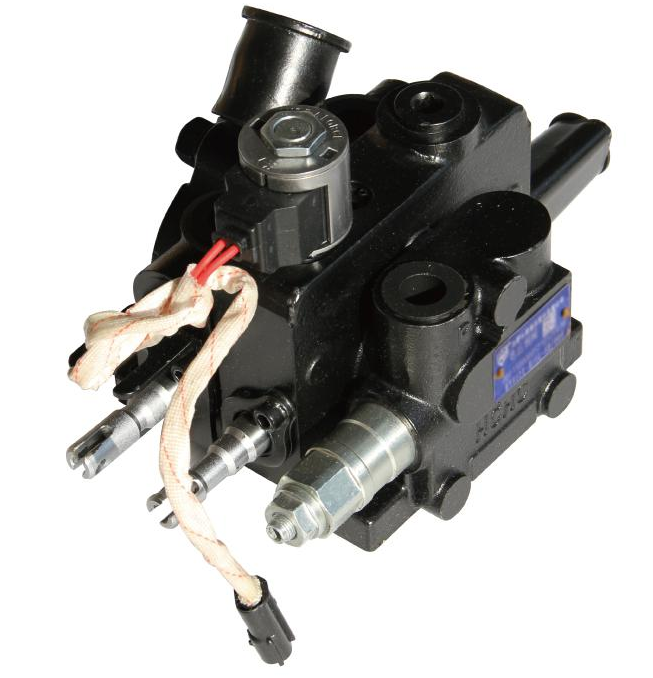

EYF*-15Multiway valve

Load-sensitive electro-hydraulic proportional multi-way valves

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Application Solutions

- Application solutions for hydraulic components for grader

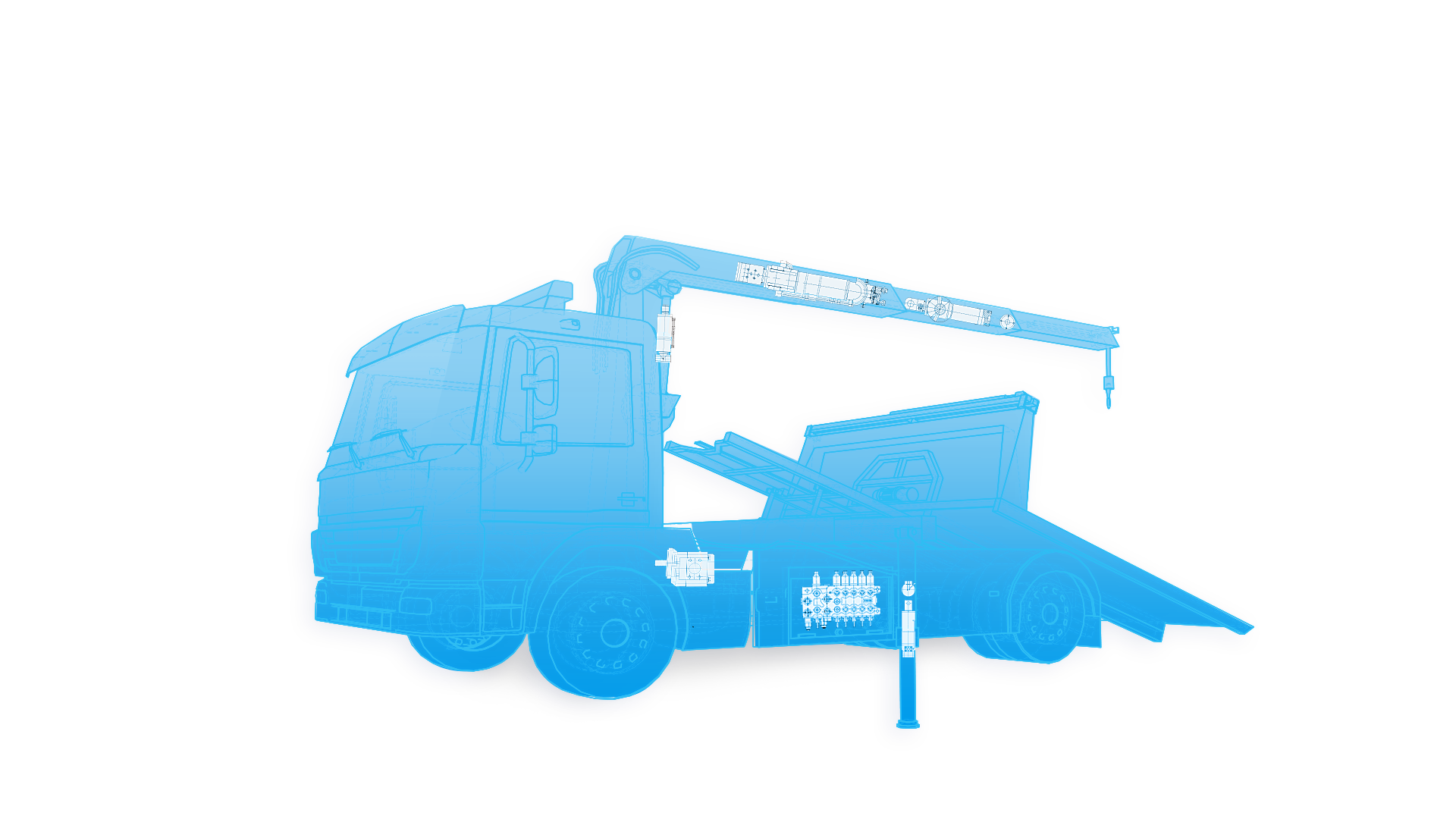

- Application solutions for hydraulic components for truck-mounted cranes

- Application solutions for rock driller fluid components

- Harvester hydraulic components application solutions

- Internal combustion forklift application solutions

- Electric forklift application solutions

- Application scheme of hydraulic components for garbage compactor

- Application solutions for tractor hydraulic components

- Application solutions for wind power hydraulic components

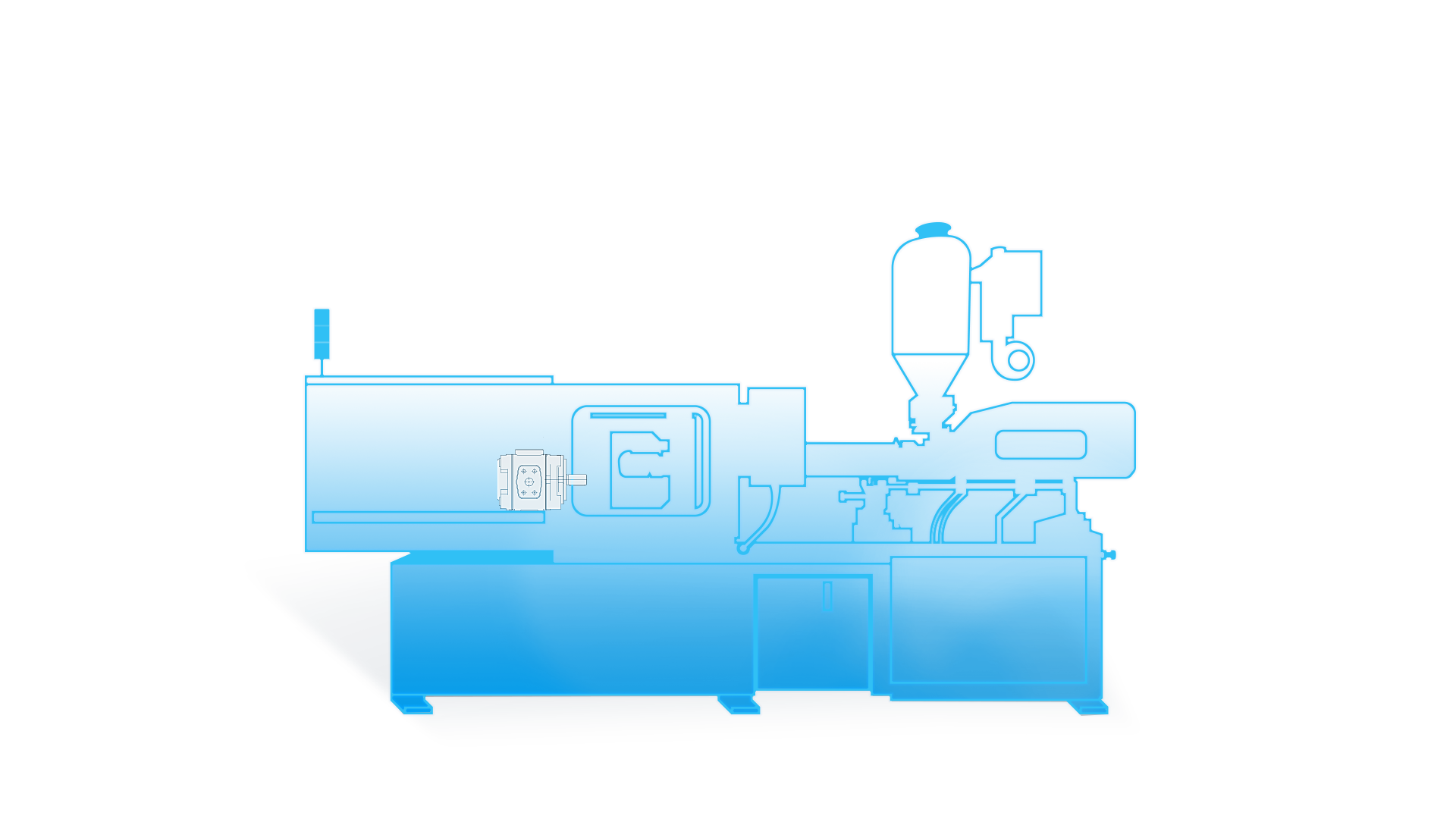

- Application solutions for hydraulic components for injection molding machines

-

Service Support

-

News

-

Join Us

Application solutions for hydraulic components for grader

-

+

Gear oil pump

0Gear oil pump

CBTLZTD / FA series

Duplex gear oil pump (cast iron)

Discription of specification:

◎ Adopting high-strength cast iron material casing with high load-bearing capacity; ◎ Adopting patented technology structure design and self-lubricating bearing application to improve oil pump working pressure and maintain high volumetric efficiency; ◎ The oil inlet and outlet connection forms are available in thread and flange; ◎ Conform to SAE standards; ◎ Rear cover with relief valve.Specification:

front and rear pumps : 06~40mL/r ; Rated pressure: 20MPa,peak pressure: 25MPa; Rated speed: 2500r/min,speed range: 800~3000r/min; Volumetric efficiency: ην≥92 %; The relief valve opening pressure is 21±0.5MPa。 -

+

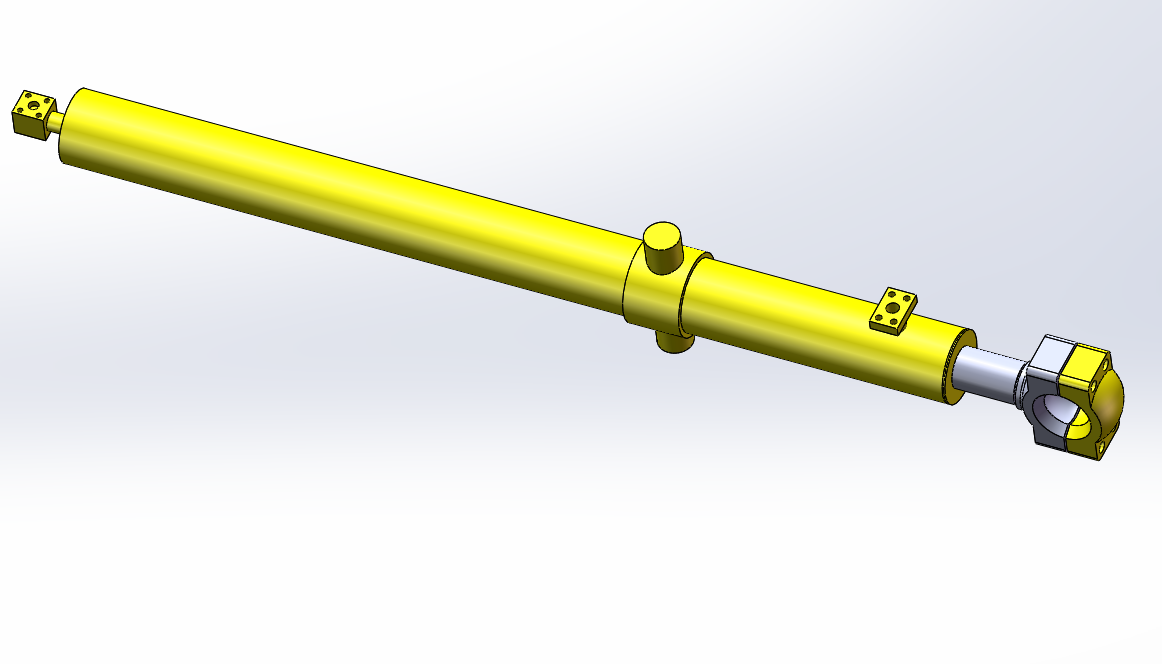

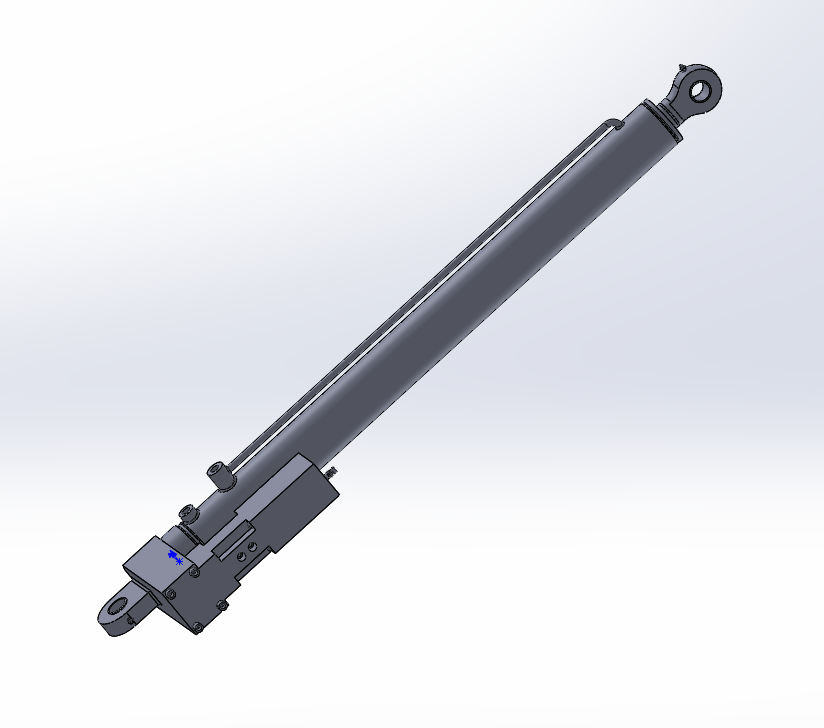

Shovel lifting cylinder

1Shovel lifting cylinder

Shovel lifting cylinder

HSGR95/65-1163×650

Discription of specification:

Suitable material is selected according to the working pressure, with advanced scraping and rolling process to make the bore keep good roughness, straightness and surface hardness, cylinder barrel is stronger and lighter; using high quality carbon structural steel or alloy steel material, adopting modulation, medium frequency, grinding and polishing process to ensure the strength, straightness and roughness of the piston rod, and adopting Atotech high efficiency chrome plating process to ensure the hardness of the chrome plating layer and the number of micro cracks. thus improving the wear and corrosion resistance of the piston rod; the trunnion and ball hinge mounting method is more suitable for complex road conditions.Specification:

Cylinder bore: 95mm, rod bore: 65mm, stroke: 1163mm; installation distance: 650mm, working pressure 21MPa -

+

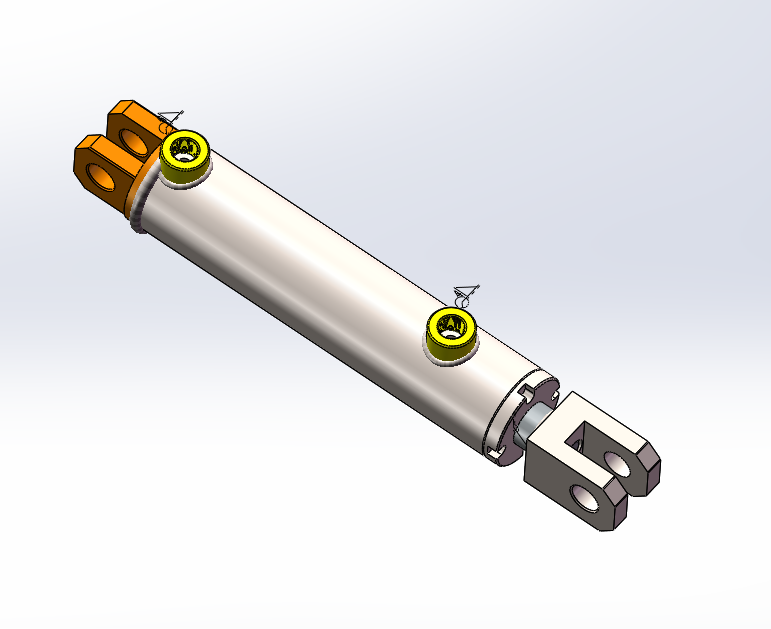

Steering cylinder

2Steering cylinder

Steering cylinder

HSG150/85-530×940

Discription of specification:

According to the working pressure, suitable material is selected, with advanced scraping and rolling process to make the bore keep good roughness, straightness and surface hardness, cylinder barrel is stronger and lighter; using high quality carbon structural steel or alloy steel material, adopting modulation, medium frequency, grinding and polishing process to ensure the strength, straightness and roughness of the piston rod, and adopting Atotech high efficiency chrome plating process to ensure the hardness of the chrome plating layer and the number of micro cracks. thereby improving the wear and corrosion resistance of the piston rod;Specification:

Cylinder bore: 150mm, rod bore: 85mm, stroke: 530mm; installation distance: 940mm, working pressure 21MPa -

+

Telescopic cylinder

3Telescopic cylinder

Loosening oil cylinder

HSG140/75-350×730

Discription of specification:

According to the working pressure, suitable material is selected, with advanced scraping and rolling process to make the bore keep good roughness, straightness and surface hardness, cylinder barrel is stronger and lighter; using high quality carbon structural steel or alloy steel material, adopting modulation, medium frequency, grinding and polishing process to ensure the strength, straightness and roughness of the piston rod, and adopting Atotech high efficiency chrome plating process to ensure the hardness of the chrome plating layer and the number of micro cracks. thereby improving the wear and corrosion resistance of the piston rodSpecification:

Cylinder bore: 140mm, rod bore: 75mm, stroke: 350mm; installation distance: 730mm, working pressure 21MPa -

+

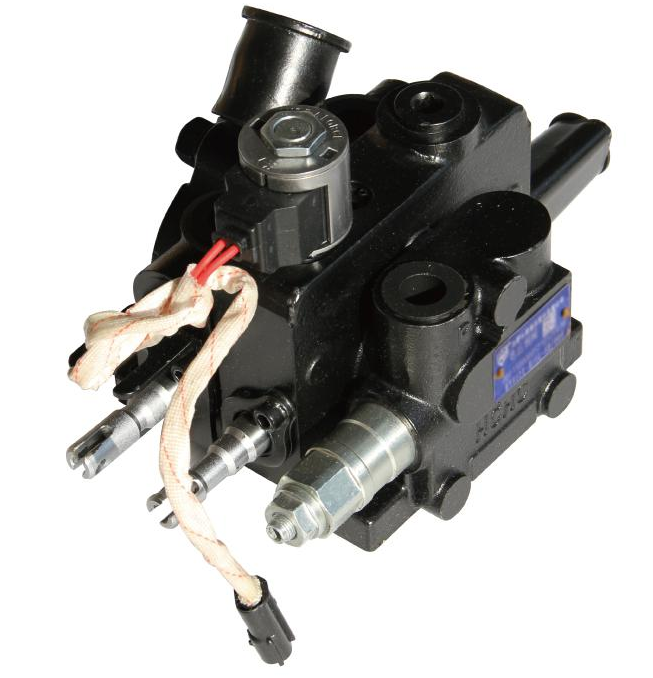

Multi-way directional valve

5Multi-way directional valve

Multi-way directional valve

DL*-15

Discription of specification:

Built-in check valve: each coupled reversing body has a built-in check valve to prevent oil backflow; Built-in relief valve: there is a pilot operated relief valve in the oil inlet body to control the system pressure; Oil circuit form: can realize parallel, series or series-parallel compound oil circuit; Additional valve: the two ends of the reversing body, according to the need to add overload valve or oil fill valve; Valve body structure: piece structure, 1~10 coupling within any combination; Valve stem neutral function: A, Z, O, Y, etc.Specification:

Nominal pressure: 20MPa; Nominal flow rate: 65L/min; Stem stroke: 7+7mm; Weight: (3.1 + 2.4 * n) Kg (n is the number of commutation body coupling).

-

Shovel lifting cylinder

Shovel lifting cylinder

Discription of specification:

◎ Adopting high-strength cast iron material casing with high load-bearing capacity; ◎ Adopting patented technology structure design and self-lubricating bearing application to improve oil pump working pressure and maintain high volumetric efficiency; ◎ Input shaft coupling form can choose flat key, rectangular spline; ◎ Conform to SAE standards.Specification:

Nominal displacement: 30/30mL/r Rated pressure: 20MPa Maximum pressure: 25MPa Rated speed: 2500r/min speed range: 800~3000r/min Volumetric efficiency: ην≥92 % The opening pressure of the safety valve is 23±0.5MPa

Application solutions for hydraulic components for truck-mounted cranes

-

+

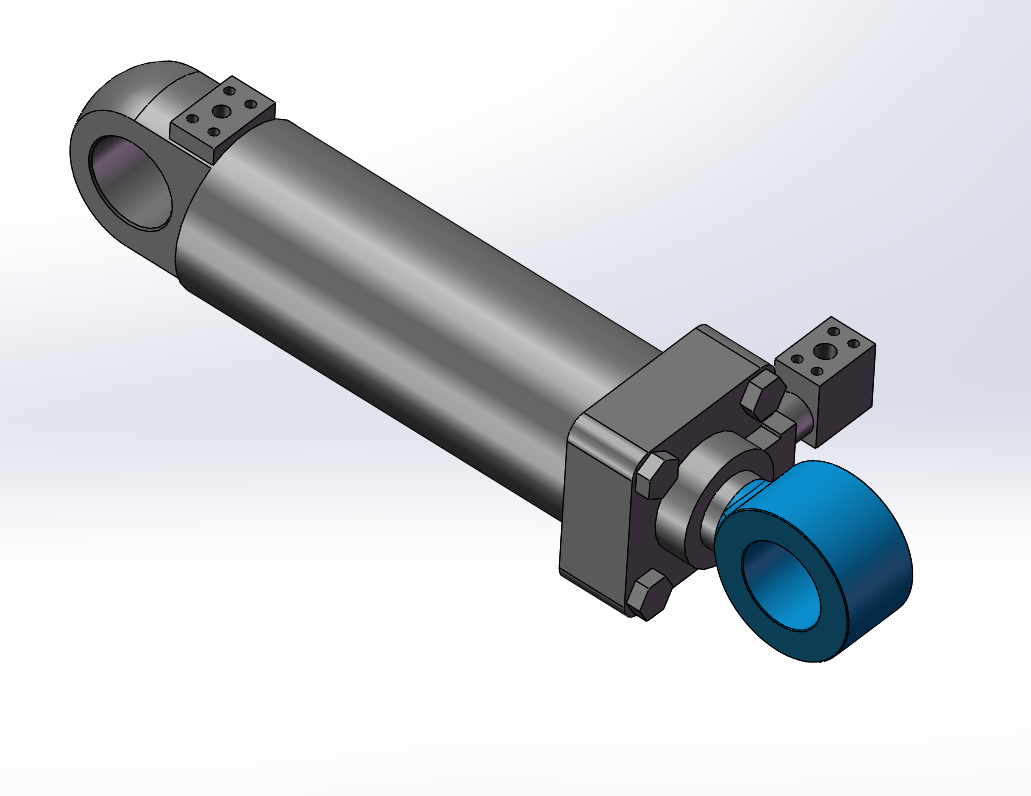

Lift arm cylinder

0Lift arm cylinder

Lift arm cylinder

HSG110/55-520*880

Discription of specification:

According to the working pressure, suitable material is selected, with advanced scraping and rolling process to make the bore keep good roughness, straightness and surface hardness, cylinder barrel is stronger and lighter; using high quality carbon structural steel or alloy steel material, adopting modulation, medium frequency, grinding and polishing process to ensure the strength, straightness and roughness of the piston rod, and adopting Atotech high efficiency chrome plating process to ensure the hardness of the chrome plating layer and the number of micro cracks, so as to improve the wear resistance and corrosion resistance of the piston rod. thereby improving the wear and corrosion resistance of the piston rod.Specification:

Cylinder bore: 110mm, rod bore: 55mm, stroke: 520mm, mounting distance: 880mm, nominal pressure: 21MPa -

+

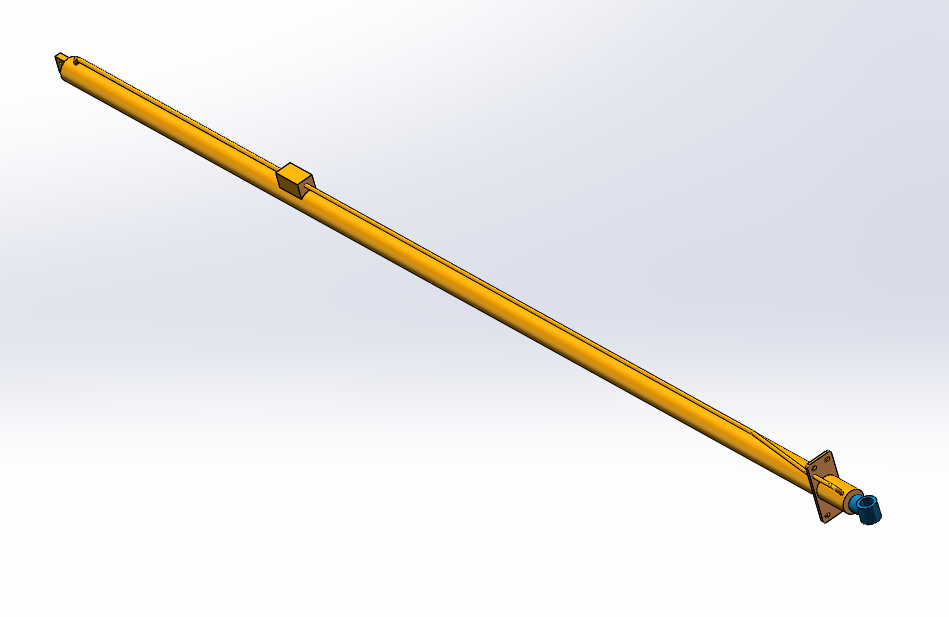

Telescopic cylinder

1Telescopic cylinder

Telescopic oil cylinder

HSG63/50-3355*196

Discription of specification:

Suitable materials are selected according to the working pressure, with advanced scraping and rolling process to make the bore keep good roughness, straightness and surface hardness, the cylinder barrel is stronger and lighter; using high quality carbon structural steel or alloy steel material, adopting modulation, medium frequency, grinding and polishing process to ensure the strength, straightness and roughness of the piston rod, and adopting Atotech high efficiency chrome plating process to ensure the hardness of the chrome plating layer and the number of micro cracks. thereby improving the wear and corrosion resistance of the piston rodSpecification:

Cylinder bore: 63mm, rod bore 50mm, stroke 3355mm, mounting distance 196mm, nominal pressure: 21MPa -

+

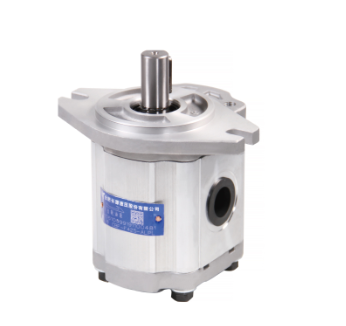

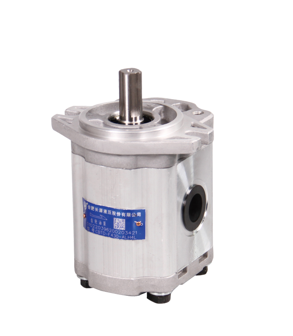

Gear pump

2Gear pump

CBGX series

Gear oil pump (cast iron)

Discription of specification:

◎ Adopting high-strength cast iron material casing with high load-bearing capacity; ◎ Adopting patented technology structure design and self-lubricating bearing application to improve oil pump working pressure and maintain high volumetric efficiency; ◎ Input shaft coupling form can choose flat key, rectangular spline.Specification:

Nominal displacement : 25 to 63mL/r; Rated pressure : 25MPa, peak pressure : 28MPa . Rated speed : 2000r/min, speed range : 800~2500r/min; Volumetric efficiency : ην≥92 %. -

+

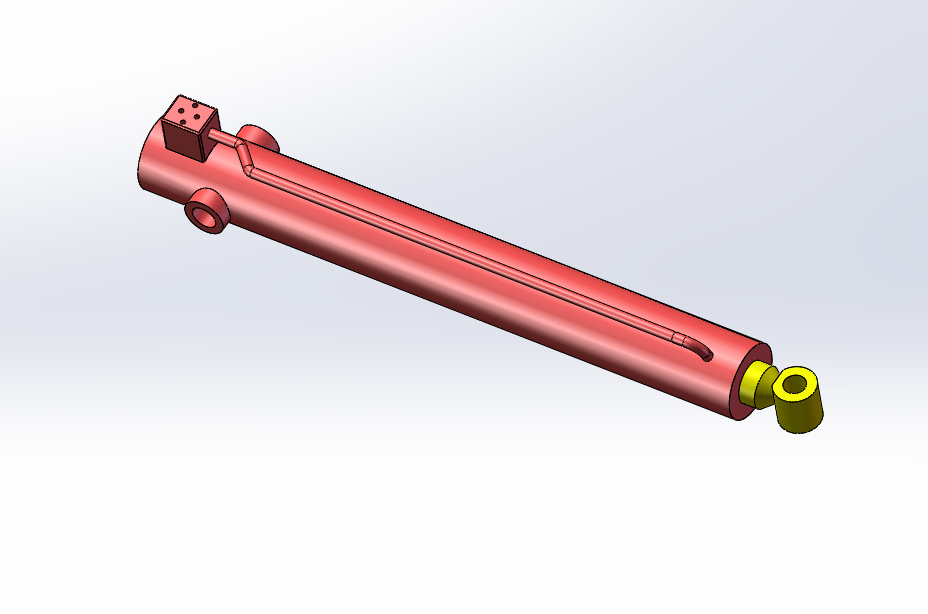

Outrigger cylinder

3Outrigger cylinder

Outrigger cylinder

HSG70/50-600*711

Discription of specification:

According to the working pressure, suitable material is selected, with advanced scraping and rolling process to make the bore keep good roughness, straightness and surface hardness, cylinder barrel is stronger and lighter; using high quality carbon structural steel or alloy steel material, adopting modulation, medium frequency, grinding and polishing process to ensure the strength, straightness and roughness of the piston rod, and adopting Atotech high efficiency chrome plating process to ensure the hardness of the chrome plating layer and the number of micro cracks. thereby improving the wear and corrosion resistance of the piston rodSpecification:

Cylinder bore: 70mm, rod bore 50mm, stroke 600mm, mounting distance 711mm, nominal pressure: 21MPa -

+

Multi-way directional valve

4Multi-way directional valve

Load sensitive multiway valve

DYCDBF*-15 series

Discription of specification:

OPS function: The lifting link can be equipped with OPS function according to demand to avoid the gantry from falling due to misoperation. Further ensure the safety of the work site. Built-in priority valve: the oil inlet body part has a priority valve, which provides flow for the steering system on a priority basis and does not provide steering flow when not steering. Additional valves: At both ends of the reversing body, different pressure overload valves or oil fill valves can be added at different oil ports according to customer needs. Built-in check valve: each coupled reversing body has built-in check valve to prevent backflow of oil Set the valve stem self-locking: prevent the forklift gantry from vibrating due to the negative pressure inside the tilting cylinder, and lock the tilting cylinder when the engine is off. Avoiding the forklift door frame from being tilted back and forth due to disoperation, which may cause safety hazards Set double safety valves: the main safety valve controls the pressure of the system, and the diverter safety valve ensures the normal working pressure of the steering system. Additional valve: the two ends of the directional body can be added with overload valve or oil fill valve according to the need Valve body structure: piece structure, any combination within 1~10 couplings Valve stem neutral function: A, Z, O, Y, etc.Specification:

Nominal pressure: 25MPa; Nominal flow: 80L/min; Stem stroke: 7+7mm

-

Multi-way directional valve

DCDB*-15 series

Discription of specification:

Built-in check valve: each linkage reversing body has built-in check valve to prevent backflow of oil; Set the valve stem self-locking: prevent the forklift gantry from vibrating due to the negative pressure inside the tilting cylinder, and lock the tilting cylinder when the engine is off; Avoiding the forklift door frame from being tilted back and forth due to disoperation, which may cause safety hazards; Descent protection solenoid valve: The controlled descent operation is effective only after this solenoid valve is opened; Additional valve: the two ends of the directional body can be added with overload valve or oil fill valve according to the need; Valve body structure: piece structure, any combination within 1~10 couplings; Valve stem neutral function: A, Z, O, Y, etc.Specification:

Nominal pressure: 20MPa; Nominal flow: 65L/min; Stem stroke: 7+7mm; Weight: 4.05+(3.1*n) Kg (n is the number of reversing body coupling) -

多路换向阀

YCDB*-15 series

Discription of specification:

Set double safety valves: the main safety valve controls the pressure of the system, and the diverter safety valve ensures the normal working pressure of the steering system; Ensure the normal working pressure of the steering system; Additional valve: the two ends of the steering body can be added with overload valve or oil fill valve according to the need; Valve body structure: piece structure, any combination within 1~10 couplings; Valve stem neutral function: A, Z, O, Y, etc.Specification:

Nominal pressure: 20MPa; Nominal flow: 65L/min; Stem stroke: 7+7mm; Weight: (5.8+2.6*n)Kg (n is the number of reversing body coupling) -

Multi-way directional valve

YCDC*-15 series

Discription of specification:

Built-in priority valve: The inlet body part has a priority valve to provide priority flow to the steering system. Lowering protection solenoid valve: only after opening this solenoid valve, the operation of controlling lowering is effective Unloading solenoid valve: only after this solenoid valve is opened, the gantry lift and tilt, the operation of the belongings is effective Built-in check valve: each linkage reversing body has built-in check valve to prevent oil backflow Set the valve stem self-locking: to prevent the forklift door frame from vibrating due to the negative pressure inside the tilting cylinder. And lock the tilting cylinder when the engine is off to avoid the forklift gantry from tilting forward by mistake, which may cause safety hazards. Set double safety valves: the main safety valve controls the pressure of the system, and the diverter safety valve ensures the normal working pressure of the steering system. Additional valve: the two ends of the steering body can be added with overload valve or oil filler valve according to the need. Valve body structure: piece structure, any combination within 1~10 couplings Valve stem neutral function: A, Z, O, Y, etc.Specification:

Nominal pressure: 20MPa; Nominal flow: 65L/min; Stem stroke: 7+7mm; Weight: (6+2.6*n)Kg (n is the number of reversing body coupling) -

Multi-way directional valve

CDB*-20

Discription of specification:

内置稳流阀:进油体部件带有稳流调,为转向系统提供稳定的流量 内置单向阀:每联换向体都有内置单向调,防止油液倒流 设置双进油口:可实现双泵合流,满足大流量液压系统需要 设置阀杆自锁:防止叉车门架因倾斜红内部负压可能引起的振动 并且当发动机熄火时锁住倾斜缸,避免误动作使叉车门架前后倾斜,造成安全隐患 设置双安全调:主安全阀控制系统压力,分流安全阀保证转向系统正常工作压力 附加闲:换向体的两端,根据需要可加过载阀或补油阀 闲体结构:片式结构,1~8联内任意组合 。闲杆中位机能: A、Z、O、Y等Specification:

Nominal pressure: 20MPa; Nominal flow: 100L/min; Stem stroke: 8+8mm ; Weight: (10.4+5.6*n)Kg (n is the number of reversing body coupling)

Application solutions for rock driller fluid components

-

+

Gear pump

0Gear pump

CBGTGC series

Multi-link gear oil pump (cast iron)

Discription of specification:

◎ Adopting high-strength cast iron material casing with high load-bearing capacity; ◎ Adopting patented technology structure design, self-lubricating bearing application, which makes the gear pump with working, high pressure, high volumetric efficiency and high reliability; ◎ Lightweight design, advanced side plate structure, special coating on the surface to improve the product pressure resistance and anti-wear; ◎ Input shaft coupling form can choose flat key, rectangular spline, SAE involute spline, metric involute spline; ◎ Conform to SAE standard; ◎ Multiple unit combinations of 4, 3 and 2 displacements are possible.Specification:

Nominal displacement of front and middle pumps : 25 to 120mL/r, nominal displacement of rear pumps : 06 to 25mL/r; Rated pressure: 23MPa, peak pressure: 28MPa; Rated speed: 1500r/min, speed range: 800 to 2500r/min; Volumetric efficiency: ην≥92 %. -

+

Lift arm cylinder

1Lift arm cylinder

Lift arm cylinder

HSG110/55-520*880

Discription of specification:

According to the working pressure, suitable material is selected, with advanced scraping and rolling process to make the bore keep good roughness, straightness and surface hardness, cylinder barrel is stronger and lighter; using high quality carbon structural steel or alloy steel material, adopting modulation, medium frequency, grinding and polishing process to ensure the strength, straightness and roughness of the piston rod, and adopting Atotech high efficiency chrome plating process to ensure the hardness of the chrome plating layer and the number of micro cracks, so as to improve the wear resistance and corrosion resistance of the piston rod. thereby improving the wear and corrosion resistance of the piston rod.Specification:

Cylinder bore: 110mm, rod bore: 55mm, stroke: 520mm, mounting distance: 880mm, nominal pressure: 21MPa -

+

Variable angle cylinder

2Variable angle cylinder

Variable angle cylinder

HSG125/63-500*1250

Discription of specification:

According to the working pressure, suitable material is selected, with advanced scraping and rolling process to make the bore keep good roughness, straightness and surface hardness, cylinder barrel is stronger and lighter; using high quality carbon structural steel or alloy steel material, adopting modulation, medium frequency, grinding and polishing process to ensure the strength, straightness and roughness of the piston rod, and adopting Atotech high efficiency chrome plating process to ensure the hardness of the chrome plating layer and the number of micro cracks. thereby improving the wear and corrosion resistance of the piston rod.Specification:

Cylinder bore: 125mm, rod bore: 63mm, stroke: 500mm; installation distance: 1250mm, working pressure 21MPa -

+

Telescopic cylinder

3Telescopic cylinder

Telescopic oil cylinder

HSG100/80-3500*220

Discription of specification:

Suitable materials are selected according to the working pressure, with advanced scraping and rolling process to make the bore keep good roughness, straightness and surface hardness, the cylinder barrel is stronger and lighter; using high quality carbon structural steel or alloy steel material, adopting modulation, medium frequency, grinding and polishing process to ensure the strength, straightness and roughness of the piston rod, and adopting Atotech high efficiency chrome plating process to ensure the hardness of the chrome plating layer and the number of micro cracks. thereby improving the wear and corrosion resistance of the piston rodSpecification:

Cylinder bore: 100mm, rod bore: 80mm, stroke: 3500mm; installation distance: 220mm, working pressure 21MPa -

+

Multi-way directional valve

4Multi-way directional valve

Multi-way directional valve

YCDB*-15

Discription of specification:

Built-in priority valve: The inlet body part has a priority valve to provide priority flow to the steering system. Built-in check valve: each linkage reversing body has built-in check valve to prevent backflow of oil Set the valve stem self-locking: prevent the forklift door frame from vibrating due to the negative pressure inside the tilting cylinder. And lock the tilting cylinder when the engine is turned off to avoid the forklift gantry from tilting forward due to the wrong action. Avoiding the forklift door frame from tilting forward by mistake, which may cause safety hazards Set double safety valves: the main safety valve controls the pressure of the system and the diversion safety valve Ensure the normal working pressure of the steering system Additional valve: the two ends of the steering body can be added with overload valve or oil fill valve as needed Valve body structure: piece structure, 1~10 couplings in any combinationSpecification:

Nominal pressure: 20MPa; Nominal flow: 50L/min; Stem stroke: 7+7mm; Weight: (5.8+2.6*n) Kg (n is the number of reversing body coupling)

-

Multi-way directional valve

YCDB*-20 series

Discription of specification:

Built-in priority valve: The inlet body part has a priority valve to provide priority flow to the steering system. Built-in check valve: each coupled reversing body has a built-in check valve to prevent oil backflow Set the valve stem self-locking: prevent the forklift gantry from vibrating due to the negative pressure inside the tilting cylinder, and lock the tilting cylinder when the engine is off. Avoiding the forklift door frame from being tilted back and forth due to disoperation, which may cause safety hazards Set double safety valves: the main safety valve controls the pressure of the system, and the diverter safety valve ensures the normal working pressure of the steering syste. Additional valve: the two ends of the steering body can be added with overload valve or oil filler valve according to the need. Valve body structure: piece structure, any combination within 1~10 couplings; Valve stem neutral function: A, Z, O, Y, etc.Specification:

Nominal pressure: 20MPa ; Nominal flow: 160L/min; Stem stroke: 8+8mm; Weight: (11+5.6*n)Kg (n is the number of reversing body coupling) -

Multi-way directional valve

DYDLa*-15 series

Discription of specification:

Built-in check valve: each linkage reversing body has built-in check valve to prevent backflow of oil Built-in relief valve: there is a pilot operated relief valve in the oil inlet body to control the system pressure Oil circuit form: can realize parallel, series or series-parallel compound oil circuit Additional valve: the two ends of the steering body can be added with overload valve or oil fill valve as needed Valve body structure: piece structure, 1~10 couplings in any combination Valve stems neutral function: A, O, Y, etc.Specification:

Nominal pressure: 20MPa ; Nominal flow: 65L/min ; Stem stroke: 7+7mm; Weight: (4.4+5.1*n)Kg (n is the number of reversing body coupling) -

Multi-way directional valve

DYDLa*-20 series

Discription of specification:

Built-in check valve: each linkage reversing body has built-in check valve to prevent backflow of oil; Built-in relief valve: there is a pilot operated relief valve in the oil inlet body to control the system pressure; Oil circuit form: can realize parallel, series or series-parallel compound oil circuit; Additional valve: the two ends of the reversing body, according to the need to add overload; Valve body structure: piece structure, 1~10 coupling within any combination; Valve stem neutral function: A, O, Y, etc.Specification:

Nominal pressure: 20MPa; Nominal flow: 65L/min; Stem stroke: 7+7mm; Weight: (1.65+2.9*n)Kg ((n is the number of reversing body coupling)

Harvester hydraulic components application solutions

-

+

Lifting cylinder

0Lifting cylinder

Lifting cylinder

HSG125/70-300*645

Discription of specification:

According to the working pressure, suitable material is selected, with advanced scraping and rolling process to make the bore keep good roughness, straightness and surface hardness, cylinder barrel is stronger and lighter; using high quality carbon structural steel or alloy steel material, adopting modulation, medium frequency, grinding and polishing process to ensure the strength, straightness and roughness of the piston rod, and adopting Atotech high efficiency chrome plating process to ensure the hardness of the chrome plating layer and the number of micro cracks. thereby improving the wear and corrosion resistance of the piston rodSpecification:

Cylinder bore: 125mm, rod bore: 70mm, stroke: 300mm; installation distance: 645mm, working pressure 21MPa -

+

Angle change oil cylinder

1Angle change oil cylinder

Angle change oil cylinder

HSG01-70/40-210*560

Discription of specification:

According to the working pressure, suitable material is selected, with advanced scraping and rolling process to make the bore keep good roughness, straightness and surface hardness, cylinder barrel is stronger and lighter; using high quality carbon structural steel or alloy steel material, adopting modulation, medium frequency, grinding and polishing process to ensure the strength, straightness and roughness of the piston rod, and adopting Atotech high efficiency chrome plating process to ensure the hardness of the chrome plating layer and the number of micro cracks. thereby improving the wear and corrosion resistance of the piston rodSpecification:

Cylinder bore: 70mm, rod bore: 40mm, stroke: 210mm; installation distance: 560mm, working pressure 21MPa -

+

Gear pump

2Gear pump

CBWLKGY

Duplex gear oil pump (aluminum alloy)

Discription of specification:

◎ Application of high strength aluminum alloy material, light weight and easy installation; ◎ Automatic compensation mechanism for axial clearance and radial hydraulic balance to maintain high volumetric efficiency of the oil pump; ◎ Adoption of self-lubricating bearings to improve the pump's load-bearing capacity; ◎ Inlet and outlet coupling forms such as thread and flange are available; ◎ Input shaft coupling form can choose flat key, rectangular spline, semi-round key, involute spline, SAE spline can be customized.Specification:

Nominal displacement : 05 to 20mL/r; Rated pressure: 20MPa, peak pressure: 25MPa; Rated speed : 2500r/min, speed range : 800 to 3000r/min; Volumetric efficiency : ην≥92 %. -

+

Multi-way directional valve

3Multi-way directional valve

Multi-way directional valve

DLS*-15

Discription of specification:

DCDB*-15 series multi-way valve is used for electric forklift, which not only meets forklift lifting, tilting and attachments control, but also adds down protection solenoid valve and emergency manual switch valve, etc. This valve can realize automatic protection of forklift gantry system after the operator leaves the forklift, which can completely avoid the safety hazards caused by disoperation. The valve is also equipped with a self-locking stem to prevent the forklift gantry from vibrating due to the negative pressure inside the tilting cylinder, and to lock the tilting cylinder when the engine is off to avoid the forklift gantry from tilting forward due to disoperation, which will cause safety hazards. dcdb*-15 series multi-way valve has complete functions, advanced performance, compact structure, safety and reliability, convenient maintenance, etc.Specification:

Nominal pressure: 16MPa; Nominal flow: 50L/min; Stem stroke: 7.5+7.5mm; Weight: 5+(3.4*n)Kg (n is the number of reversing body coupling)

-

Solenoid Valve

DCF*-50

Discription of specification:

DCF*-50 series solenoid valve is composed of inlet valve piece, directional valve piece and return valve piece, the control mode is electric control. The valve has a compact structure. Each port can be configured with an integral hydraulic lock, which can effectively control the amount of leakage within the neutral position of the multi-way valve, the safety valve is a direct-acting safety valve, with good anti-pollution properties. Widely used in agricultural receiving machinery and other mechanical hydraulic systems. Built-in hydraulic locks: each reversing body can be configured with integral hydraulic locks to effectively control internal leakage. Built-in relief valve: direct-acting relief valve is set in the oil inlet, with strong anti-pollution performance. Oil circuit type: parallel oil circuitSpecification:

Rated pressure: 31.5MPa; Nominal flow: 50L /Min; The safety valve sets the pressure: 16±0.5MPa; Solenoid valve voltage: 24V(DC); Solenoid valve power:30W.

Internal combustion forklift application solutions

Electric forklift application solutions

内燃叉车解决方案

电动叉车解决方案

-

+

Gear pump

0Gear pump

CBHV series

Single link gear oil pump

Discription of specification:

◎ Environmentally friendly patented product with noise value ≤ 60dB; ◎ Adopting no side gap gear technology, axial automatic compensation structure, radial hydraulic balance, ensuring high volumetric efficiency and high reliability of the oil pump; ◎ Adopting high-strength, high-vibration-absorbing cast iron material shell; ◎ The oil inlet and outlet are back-in and back-out, back-in and side-out, side-in and side-out, etc; ◎ Input shaft coupling form can choose flat key, rectangular spline, SAE involute spline.Specification:

Nominal displacement : 15 to 32mL/r; Rated pressure : 20MPa, peak pressure : 25MPa; Rated speed : 2500r/min, speed range : 400 to 3000r/min; Volumetric efficiency : ην≥94 %. -

+

Forklift tilting cylinder

1Forklift tilting cylinder

Forklift tilting cylinder

HSG63/35-120*330

Discription of specification:

According to the working pressure choose the suitable material, with advanced scraping and rolling process makes the bore keep good roughness, straightness and surface hardness, cylinder barrel is stronger and lighter; use high quality carbon structural steel or alloy steel material, adopt modulation, medium frequency, grinding and polishing process to ensure the strength, straightness and roughness of the piston rod, and adopt Atotech high efficiency chrome plating process to ensure the hardness of the chrome plating layer and the number of micro cracks. thereby improving the wear and corrosion resistance of the piston rodSpecification:

Cylinder bore: 63mm, rod bore: 35mm, stroke: 120mm; installation distance: 330mm, working pressure: 21MPa -

+

Rear wheel steering cylinder

2Rear wheel steering cylinder

Rear wheel steering cylinder

HSG63/32-150*365

Discription of specification:

Suitable materials are selected according to the working pressure, with advanced scraping and rolling process to make the bore keep good roughness, straightness and surface hardness, the cylinder barrel is stronger and lighter; using high quality carbon structural steel or alloy steel material, adopting modulation, medium frequency, grinding and polishing processes to ensure the strength, straightness and roughness of the piston rod, and adopting Atotech high efficiency chrome plating process to ensure the hardness of the chrome plating layer and the number of micro cracks. thereby improving the wear and corrosion resistance of the piston rodSpecification:

Cylinder bore: 63mm, rod bore: 32mm, stroke: 150mm; installation distance: 365mm, working pressure: 21MPa -

+

Multi-way directional valve

3Multi-way directional valve

Multi-way directional valve

DCDB*-15

Discription of specification:

DCDB*-15 series multi-way valve is used for electric forklift, which not only meets forklift lifting, tilting and attachments control, but also adds down protection solenoid valve and emergency manual switch valve, etc. This valve can realize automatic protection of forklift gantry system after the operator leaves the forklift, which can completely avoid the safety hazards caused by disoperation. The valve is also equipped with a self-locking stem to prevent the forklift gantry from vibrating due to the negative pressure inside the tilting cylinder, and to lock the tilting cylinder when the engine is off to avoid the forklift gantry from tilting forward due to disoperation, which will cause safety hazards. dcdb*-15 series multi-way valve has complete functions, advanced performance, compact structure, safety and reliability, convenient maintenance, etc.Specification:

Nominal pressure: 20MPa; Nominal flow: 65L/min; Stem stroke: 7+7mm; Weight: 1.65+(2.9*n) Kg (n is the number of reversing body coupling)

-

power brake valve

OBV-25

Discription of specification:

Shared Hydraulic System: The power brake valves share the hydraulic fluid source of the steering system to charge the accumulators and brake the valves; when the engine is off, the power brakes utilize the pressurized fluid stored in the accumulators to apply the brakes. Overload unloading: Accumulator built-in relief valve, automatic unloading after exceeding the set pressure Under Pressure Alarm: Accumulator built-in alarm, when the accumulator pressure is lower than the set pressure, the alarm alarm, prompting the operator to charge the accumulator liquid Full-featured: the combination of power brake valve and accumulator can well meet the braking function of forklift trucks in three working conditions: traveling, stopping and emergency stopping. Comfortable Foot Feeling: the pedal force is linearly proportional to the output pressure of the brake valve, which makes the foot feeling light and comfortable. Unloading safety valve: The use of E45E5-40211 safety valve can make the brake fluid will not flow back completely when unloading, to ensure that the brake is filled quickly and the brake is more reliable when braking again.Specification:

Nominal pressure: 16MPa; Nominal flow: 25L/min; Weight: 2Kg

-

+

Gear pump

0Gear pump

CBHZ series

Single link gear oil pump

Discription of specification:

◎ Adopting asymmetric tooth shape double modulus gear, axial automatic compensation structure, radial hydraulic balance to ensure high volume efficiency and high reliability of the oil pump; ◎ Adopting high-strength and warm-resistant cast iron material shell with high load-bearing capacity; ◎ Adopting self-lubricating bearings to improve the bearing capacity of the pump; ◎ High volumetric efficiency can be maintained at a speed of 600rpm; Input shaft coupling form can choose flat key, rectangular spline, SAE spline, involute spline .Specification:

Nominal displacement : 23 to 40mL/r; Rated pressure : 20MPa Peak pressure : 25MPa; Rated speed : 2500r/min Rotational speed range : 600~3000r/min; Volumetric efficiency : ην≥92 %. -

+

Forklift tilting cylinder

1Forklift tilting cylinder

Forklift tilting cylinder

HSG63/35-120*330

Discription of specification:

According to the working pressure choose the suitable material, with advanced scraping and rolling process makes the bore keep good roughness, straightness and surface hardness, cylinder barrel is stronger and lighter; use high quality carbon structural steel or alloy steel material, adopt modulation, medium frequency, grinding and polishing process to ensure the strength, straightness and roughness of the piston rod, and adopt Atotech high efficiency chrome plating process to ensure the hardness of the chrome plating layer and the number of micro cracks. thereby improving the wear and corrosion resistance of the piston rodSpecification:

Cylinder bore: 63mm, rod bore: 35mm, stroke: 120mm; installation distance: 330mm, working pressure: 21MPa -

+

Rear wheel steering cylinder

2Rear wheel steering cylinder

Rear wheel steering cylinder

HSG63/32-150*365

Discription of specification:

Suitable materials are selected according to the working pressure, with advanced scraping and rolling process to make the bore keep good roughness, straightness and surface hardness, the cylinder barrel is stronger and lighter; using high quality carbon structural steel or alloy steel material, adopting modulation, medium frequency, grinding and polishing processes to ensure the strength, straightness and roughness of the piston rod, and adopting Atotech high efficiency chrome plating process to ensure the hardness of the chrome plating layer and the number of micro cracks. thereby improving the wear and corrosion resistance of the piston rod.Specification:

Cylinder bore: 63mm, rod bore: 32mm, stroke: 150mm; installation distance: 365mm, working pressure: 21MPa -

+

Multi-way directional valve

3Multi-way directional valve

Multi-way directional valve

CDB*-15

Discription of specification:

Built-in flow stabilizer valve: the oil inlet part is equipped with a flow stabilizer valve to provide stable flow for the steering system. Built-in check valve: Each reversing body has a built-in check valve to prevent backflow of oil. Dual inlet: dual pumps can be combined to meet the needs of large flow hydraulic systems. Setting the valve stem self-locking: to prevent the forklift truck door frame from vibrating due to the negative pressure inside the tilting cylinder, and to lock the valve stem when the engine is off. And lock the tilting cylinder when the engine is turned off to avoid tilting the forklift frame back and forth due to malfunction, which may cause safety hazards. Dual safety valves: the main safety valve controls the system pressure, and the shunt safety valve ensures the normal working pressure of the steering system. Additional valves: at both ends of the reversing body, an overload valve or a replenishment valve can be added according to the need. Valve body structure: Piece structure, any combination within 1~8 links. Valve stem center function: A, Z, O, Y, etc.Specification:

Nominal pressure: 20MPa; Nominal flow: 60L/min; Stem stroke: 7+7mm ; Weight: 4+(2.6*n)Kg (n is the number of reversing body coupling)

-

speed limiting valves

XSFα series

Discription of specification:

XSFα series speed limiting valves are compact and reliable, widely used in forklift truck gantry descending hydraulic system, which can limit the descending speed of the gantry and ensure the smooth operation of the hydraulic system.Specification:

-

external gear pump

OBV-25 power brake valve

Discription of specification:

Shared Hydraulic System: The power brake valves share the hydraulic fluid source of the steering system to charge the accumulators and brake the valves; when the engine is off, the power brakes utilize the pressurized fluid stored in the accumulators to apply the brakes. Overload unloading: Accumulator built-in relief valve, automatic unloading after exceeding the set pressure Under Pressure Alarm: Accumulator built-in alarm, when the accumulator pressure is lower than the set pressure, the alarm alarm, prompting the operator to charge the accumulator liquid Full-featured: the combination of power brake valve and accumulator can well meet the braking function of forklift trucks in three working conditions: traveling, stopping and emergency stopping. Comfortable Foot Feeling: the pedal force is linearly proportional to the output pressure of the brake valve, which makes the foot feeling light and comfortable. Unloading safety valve: The use of E45E5-40211 safety valve can make the brake fluid will not flow back completely when unloading, to ensure that the brake is filled quickly and the brake is more reliable when braking again.Specification:

Nominal pressure: 16MPa ; Nominal flow: 25L/min ;Weight: 2Kg -

brake valve

HCZF*-15 brake valve

Discription of specification:

HCZF*-15 brake valve is used in the brake system of forklift truck. The brake valve is equipped with a diverter valve, so that the constant flow for the forklift steering system can be diverted out of a very small part of the flow (500~700mL/min) through the brake valve for the brake valve to work. The brake valve is controlled by the foot pedal. When the pedal is pressed, the pedal stroke is transferred to the piston rod of the brake valve by the push rod, and under the action of the pressure reducing valve in the brake valve, a certain pressure is generated on the piston rod side of the piston to form a booster, and the hydraulic oil in the piston cavity enters the brake through the safety valve to realize the braking of the forklift truck, and the pedal force is linearly proportional to the output pressure of the brake valve with a better foot feeling. When the pedal is released, the high-pressure oil in the brake returns to the piston cavity through the safety valve, and at the same time, the replenishment valve in the brake valve opens under negative pressure to replenish the oil to the piston cavity to ensure that there is enough hydraulic oil in the piston cavity when braking again, so that it can be braked even in the case of engine shutdown. In addition, the safety valve at the outlet of the piston chamber keeps the fluid from flowing back completely when the brake is unloaded and maintains a certain pressure, which ensures rapid filling and more reliable braking when the brake is applied again.Specification:

nominal pressure: 16MPa; Nominal flow: 15L/min; Weight: 2.7Kg (n is the number of reversing body coupling)

Application scheme of hydraulic components for garbage compactor

-

+

Compression master cylinder

0Compression master cylinder

Compression master cylinder

HSG160/110-3400*2000

Discription of specification:

Suitable material is selected according to the working pressure, with advanced scraping and rolling process to make the bore keep good roughness, straightness and surface hardness, cylinder barrel is stronger and lighter; using high quality carbon structural steel or alloy steel material, adopting modulation, medium frequency, grinding and polishing process to ensure the strength, straightness and roughness of the piston rod, and adopting Atotech high efficiency chrome plating process to ensure the hardness of the chrome plating layer and the number of micro cracks. thus improving the wear and corrosion resistance of the piston rod.Specification:

Cylinder bore: 160mm, rod bore: 110mm, stroke: 3400mm; installation distance: 2000mm; working pressure: 21MPa -

+

Gear pump

1Gear pump

CBGNL series

Duplex gear oil pump (cast iron)

Discription of specification:

◎ Using high-strength cast iron material shell, strong bearing capacity; ◎ Using patented technology structure design, self-lubricating bearing application, improve the oil pump working pressure, maintain high volumetric efficiency; ◎ Input shaft coupling form can choose flat key, rectangular spline, involute spline, SAE spline; ◎ Inlet and outlet connections are available in flange, threaded, etc.Specification:

Nominal displacement of front pump: 32~63mL/r, nominal displacement of rear pump: 10~25mL/r; Rated pressure: 25MPa, peak pressure: 28MPa; Rated speed: 1500r/min, speed range: 800~2500r/min; Volumetric efficiency: ην≥92 %. -

+

Multi-way directional valve

2Multi-way directional valve

Multi-way directional valve

YCDC*-15

Discription of specification:

Built-in Priority Valve: The inlet body component has a priority valve that prioritizes flow to the steering system and does not provide steering flow when not steering. Lowering protection solenoid valve: only when this solenoid valve is opened, the lowering control operation is effective Unloading solenoid valve: only when this solenoid valve is open, the gantry lifts, tilts, and generator operation is effective. Built-in check valve: Each reversing body has a built-in check valve to prevent backflow of oil. Setting the valve stem self-locking: preventing the forklift gantry from vibrating due to the negative pressure inside the tilting cylinder, and locking the tilting cylinder when the engine is off, avoiding the tilting of the forklift gantry forward by mistake, which will cause a potential safety hazard. Setting double safety valves: main safety valve to control system pressure, shunt safety valve to ensure the normal working pressure of the steering system Additional valves: at both ends of the commutator, overload valves or make-up valves can be added according to requirements Valve body structure: piece structure, any combination within 1~10 links Stem center function: A, Z, O, Y, etc.Specification:

Nominal pressure: 20MPa ; Nominal flow: 65L/min ; Stem stroke:7+7mm; Weight: 4.05+(3.1*n)Kg (n is the number of reversing body coupling)

-

Multi-way directional valve

YCDB*-20 series

Discription of specification:

Built-in check valves: Each reversing body has a built-in check valve to prevent backflow of oil Setting valve stem self-locking: preventing the forklift gantry from vibrating due to the negative pressure inside the tilting cylinder, and locking the tilting cylinder when the engine is off, avoiding the tilting of the forklift gantry forward by malfunction, which may cause a potential safety hazard. Setting double safety valves: the main safety valve controls the system pressure, and the shunt safety valve ensures the normal working pressure of the steering system. Additional valves: at both ends of the reversing body, an overload valve or a replenishment valve can be added according to the need. Valve body structure: Piece structure, any combination within 1~10 links. Valve stem center function: A, Z, O, Y, etc.Specification:

Nominal pressure: 20MPa; Nominal flow rate: 160L/min; Stem stroke: 8+8mm;Weight: 11+(5.6*n)Kg (n is the number of commutation body coupling) -

Multi-way directional valve

HCZTF-12 series

Discription of specification:

Built-in hydraulic lock: hydraulic lock to ensure that the actuator leakage to meet user needs Built-in one-way throttle valve: one-way throttle valve can reduce the hydraulic lock closing speed. Avoid negative pressure in the cylinder, contraction is not in place Set the safety valve: control the maximum pressure of the valve group in the process of work Setting overload valve: the overload valve ensures the overload protection and safety of the actuator in the working process. Valve Body Structure: Integral StructureSpecification:

Nominal pressure: 25MPa ; Nominal flow: P-G:80L/min,P-V:120L/min Select stem travel: 8+8mm; Working stem stroke: 6+6mm.

Application solutions for tractor hydraulic components

-

+

Gear pump

0Gear pump

CBTLAW series

Duplex gear oil pump (aluminum alloy)

Discription of specification:

◎ High-strength aluminum alloy material, light weight, easy installation; automatic axial clearance compensation mechanism, radial hydraulic balance, maintain high volume efficiency of the pump; pump and valve in one, compact structure, small size; ◎ Automatic axial clearance compensation mechanism, radial hydraulic balance, maintain high volumetric efficiency of oil pump; ◎ Using self-lubricating bearings to improve the pump's load-bearing capacity; ◎ Inlet and outlet connection forms are available in thread and flange; ◎ Input shaft coupling form can be selected as flat key, rectangular spline, involute spline, SAE spline; ◎ The front and rear pumps do not cascade oil。Specification:

Nominal displacement of front and rear pumps:10~30mL/r ; Rated pressure: 20MPa, peak pressure : 25MPa ; Rated speed : 2500r/min, speed range : 800~3000r/min; volumetric efficiency:ην≥92 %。 -

+

Multi-way directional valve

1Multi-way directional valve

Multi-way directional valve

DF*-15

Discription of specification:

Built-in check valve: Each reversing body can be equipped with built-in check valve to prevent backflow of oil. Built-in relief valve: the inlet body is equipped with differential or direct-acting relief valve, which has strong pollution resistance. Additional valves: at both ends of the commutator, according to the needs of customers can be added in different oil ports, different pressure overload valves, replenishment valves. Pressure overload valve, replenishment valve, shut-off valve. Valve body structure: Piece structure, any combination within 1~8 links. Valve stem center function: A, O, YSpecification:

Nominal pressure: 20MPa ; Nominal flow: 50L/min; Stem stroke: O type, etc. 8+8mm,Q type, etc. 5+5+5mm; Weight: 4.05+(3.1*n)Kg (n is the number of reversing body coupling)

-

Multi-way directional valve

FP6G*-15 series

Discription of specification:

FP6G*-15 series integral distributor has compact structure, high working pressure and easy to use and maintain. They are widely used in the hydraulic systems of large and medium horsepower tractors and other machinery. Built-in relief valve: there is a relief valve in the inlet body to regulate the system pressure. Valve body structure: integral structure, single structure Valve stem center function: Q typeSpecification:

Nominal pressure: 20MPa ; Nominal flow: 90L/min ;Weight: 12.6Kg -

Multi-way directional valve

DLSG*-20 series

Discription of specification:

DLSG*-20 series multi-way valve has the advantages of compact structure, high working pressure, good performance, reliable work, can realize the advantages of floating actuators, and in the lifter control joint neutral position increased mechanical pilot hydraulic lock. Widely used in large and medium horsepower tractor hydraulic system. Built-in check valve: each reversing body can be individually configured with a built-in check valve, which can prevent backflow of oil. Built-in relief valve: the inlet body is equipped with differential or direct-acting relief valves, with strong resistance to pollution. Additional valves: at both ends of the commutator, according to the needs of customers can be added at different oil ports. Different pressure overload valves, replenishment valves, shut-off valves. Valve body structure: piece-type structure, any combination within 1~8 links. Valve stem center function: Q, O,Specification:

Nominal pressure: 20MPa; Nominal flow: 100L/min; Stem stroke: 7+7mm; Weight: 4.2+(5.45*n)Kg (n is the number of reversing body coupling) -

Multi-way directional valve

DF28-15 series

Discription of specification:

DF28-15 series multi-way valves have the advantages of compact structure, high working pressure, good performance, reliable work, can realize the advantages of floating actuators, and in the lifter control joint neutral position increased mechanical pilot hydraulic lock. Widely used in large and medium horsepower tractor hydraulic system. Built-in check valve: Each reversing body can be equipped with built-in check valve to prevent backflow of oil. Built-in relief valve: the inlet body is equipped with differential or direct-acting relief valve, which has strong pollution resistance. Additional valves: at both ends of the commutator, according to the needs of customers can be added in different oil ports, different pressure overload valves, replenishment valves. Different pressure overload valves, replenishment valves, shut-off valves. Valve body structure: piece-type structure, any combination within 1~8 links. Valve stem center function: Q, O,Q1Specification:

Nominal pressure: 20MPa; Nominal flow rate: 50L/min ;Stem stroke :O8+8mm,Q 5+5+5mm; Weight: 4.05+(3.1*n)Kg (n is the number of commutation body coupling) -

Multi-way directional valve

DLS*-20 series

Discription of specification:

DLS*-20 series multi-way valves have the advantages of compact structure, high working pressure, good performance, reliable operation, and floating actuator. They are widely used in hydraulic output system of large and medium horsepower tractors.。 Built-in check valve: Each reversing body can be individually equipped with built-in check valve, which can prevent backflow of oil. Built-in relief valve: the inlet body is equipped with differential or direct-acting relief valve, which has strong pollution resistance. Additional valves: at both ends of the reversing body, different pressure overload valves or replenishment valves can be added at different oil ports according to customers' needs. Different pressure overload valves, replenishment valves, shut-off valves. Valve body structure: piece-type structure, any combination within 1~8 links. Valve stem center function:Q、OSpecification:

Nominal pressure: 20MPa; Nominal flow: 100L/min; Stem stroke: 8+8mm ;Weight 4.35+(5.65*n)Kg (n is the number of reversing body coupling)

Application solutions for wind power hydraulic components

-

+

Gear pump

0Gear pump

CBRH series

Single link gear oil pump (cast iron)

Discription of specification:

◎ The shell part is made of gray cast iron with strong load-bearing capacity; ◎ Adopting high-strength alloy steel gears, with stable performance and long life; ◎ Suitable for high viscosity medium, can be used to transport all kinds of oil; ◎ Various models can be combined in any way according to the modular design principle.Specification:

Nominal Displacement : 100~200mL/r Rated pressure: 2.5MPa Peak pressure: 4MPa Rated speed: 1450r/min Rotational speed range: 200~3000r/min; Volumetric efficiency : ην≥90 %. -

+

Gear pump

1Gear pump

CBRHA series

Single link gear oil pump (cast iron)

Discription of specification:

◎ The shell part is made of gray cast iron with strong bearing capacity; ◎ The gears are made of high-strength alloy steel with stable performance and long life; ◎ it is suitable for high viscosity medium; ◎ can be used for conveying all kinds of oil and liquidSpecification:

Nominal displacement: 16~80mL/r ; Rated pressure: 2.5MPa,Peak pressure: 4MPa ; Rated speed: 1450r/min,Rotational speed range: 200~3000r/min; Volumetric efficiency: ην≥90 %。

-

hydraulic pump

hydraulic pump

Discription of specification:

◎ Adopting high-strength cast iron material casing with high load-bearing capacity; ◎ Adopting patented technology structure design, self-lubricating bearing application, improving oil pump working pressure and maintaining high volumetric efficiency; ◎ The oil inlet and outlet connection forms are available in thread and flange; ◎ Conform to SAE standards.Specification:

Nominal displacement: 30/30mL/r Rated pressure: 20MPa Maximum pressure: 25MPa Rated speed: 2500r/min Speed range : 800~3000r/min Volumetric efficiency: ην≥92 % The opening pressure of the safety valve is 23±0.5MPa

Application solutions for hydraulic components for injection molding machines

-

+

HC series internal gear pump

0HC series internal gear pump

HC1-**-R-VPC

HC series internal gear pump

Discription of specification:

• This internal gear oil pump has a wide range of speed application from 100 to 3000rpm. High operating pressure of 31.5MPa; high reliability and long operating life; • This product can be used in injection molding machines, shoe making machinery, electric forklifts and other equipment;Specification:

Displacement: 32~120mL/r Pressure: 0~31.5MPa Rotational speed: 100~3000rpm

Domestic market phone number:4008-123-910

+86-551-64391100

+86-551-64391122

Email:sale@hchc.cn

Global market phone number:+86-551-64396718

Email:export01@hchc.cn

After-sales support hotline:400-887-9946

Related links:https://ahhchc.en.alibaba.com

Related links:https://ahhchc.1688.com

Related links:https://ahhchc.en.made-in-china.com

-

ABOUT HCHC

-

Product Center

-

Application Solutions

- Application solutions for hydraulic components for grader

- Application solutions for hydraulic components for truck-mounted cranes

- Application solutions for rock driller fluid components

- Harvester hydraulic components application solutions

- Internal combustion forklift application solutions

- Electric forklift application solutions

- Application scheme of hydraulic components for garbage compactor

- Application solutions for tractor hydraulic components

- Application solutions for wind power hydraulic components

- Application solutions for hydraulic components for injection molding machines

-

Service Support

-

News

-

Join Us

Follow us on wechat

Copyright: Hefei Changyuan Hydraulic Co.,ltd [皖ICP备05012331号]

Anti-fake search

Anti-fake search