-

ABOUT HCHC

-

Product Center

Product

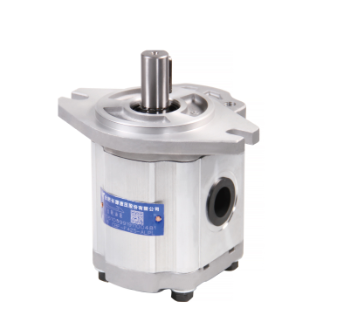

- HC internal gear pump

- CBRHA Gear pump

- CBRH Gear pump

- CBWS/F-D3 gear pump

- CBW/FB-E3 gear pump

- CBXZ-C compound gear pump

- CBWKGY gear pump

- CBGT4 gear pump

- CBF-F5 gear pump

- CBGTGC Multi-gear oil pump

- CBVH Triple gear pump

- CBKP Triple gear pump

- CBKL-G/G double gear oil pump

- CBHYG-G/F double gear oil pump

- CBHY-G/F double gear oil pump

- CBV2/2 double gear oil pump

- CBGTFL double gear oil pump

- CBKP Double gear oil pump

- CBG2/2 Double gear oil pump

- CBGTBLT Double gear oil pump

- CBGTBLA2 Double gear oil pump

- CBTLZTD-F/F Double gear oil pump

- CBTLZTA-F/F Double gear oil pump

- CBGNL Double gear oil pump

- CBNL-F5/F5 Double gear oil pump

- CBHLB-F5/F5 Double gear oil pump

- CBHLD-F5/F5 Double gear oil pump

- CBQTF Double gear oil pump

- CBQT-*5/F4 Double gear oil pump

- CBQL-*5/F5 Double gear oil pump

- CBTL-*4/*4 Double gear oil pump

- CBWL-*3/*3 CBKL-G/G

- CBKP gear pump

- CBV gear pump

- CBGTG

- CBGTF2 Gear pump

- CBZTG3 Gear pump

- CBZTG2 Gear pump

- CBGTC2 gear pump

- CBGTB2 Gear pump

- CBZTC2 Gear pump

- CBTZTD Gear pump

- CBTZTA-F Gear pump

- CBGX Gear pump

- CBNZQ -F5 Gear pump

- CBN-F5 Gear pump

- CBWma-F,CBWmb-F Gear pump

- CBW-F2 Gear pump

- CBG2 Gear pump

- CBF-F6 Gear pump

- CBQ-*5 Gear pump

- CBHB-F5 gear pump

- CBH-*5 Gear pump

- CBF-*4 Gear pump

- CBWKA-F3 Gear pump

- CBHZA-F gear pump

- CBHZ-F Gear pump

- CBHE Gear pump

- CBHV Gear pump

- CBHV Gear pump(rear inlet and outlet)

- CBHC Gear pump

- CBKEC Gear pump

- CBTD-F4 Gear pump

- CBT-F4 Gear pump

- EYF*-15Multiway valve

- HCZTF-120 Multi-way valve

- DYCDBF*-15Multiway valve

- DCFB-G60L-4 Solenoid Valve

- DCF*-50 Solenoid Valve

- XSFα* speed limiting valves

- 1WFL* Shunt valve

- SDV*-70 multi-way valves

- SDVA*-40 Multi-way valves

- SDV*-40

- SDV*-25

- ZDaG*-15 Multi-way valves

- ZDG*-15 Multi-way valves

- ZD*-10 Integral multi-way valves

- BDL*-40

- FP6G*-15

- EDL*-25 Multiway valve

- EDL*-20 Multi-way valves

- EDL*-15 Multi-way valve

- EDL*-10 Multi-way valves

- ZL*-20 Multi-way valves

- DLSG*-20 Multiway valve

- DLS*-20 Multi-way valves

- DLS*-15 Multiway valve

- DF28-15 Multiway valve

- DF*-15 Multi-way valves

- DL*-20 Multi-way valves

- DL*-15 Multi-way valves

- DYDLa*-20 Multi-way valve

- DYDLa*-15 Multi-way valve

- HCZF*-15

- OBV*/HXQ*

- YCDC*-20 Multiple directional valve

- YCDB*-20 Multiple directional valve

- CDB*-20 Multiple directional valve

- YCDC*-15

- YCDB*-15 Multiple directional valve

- DCDB*-15 Multiway valve

- CDB* -15 Multiway valve

-

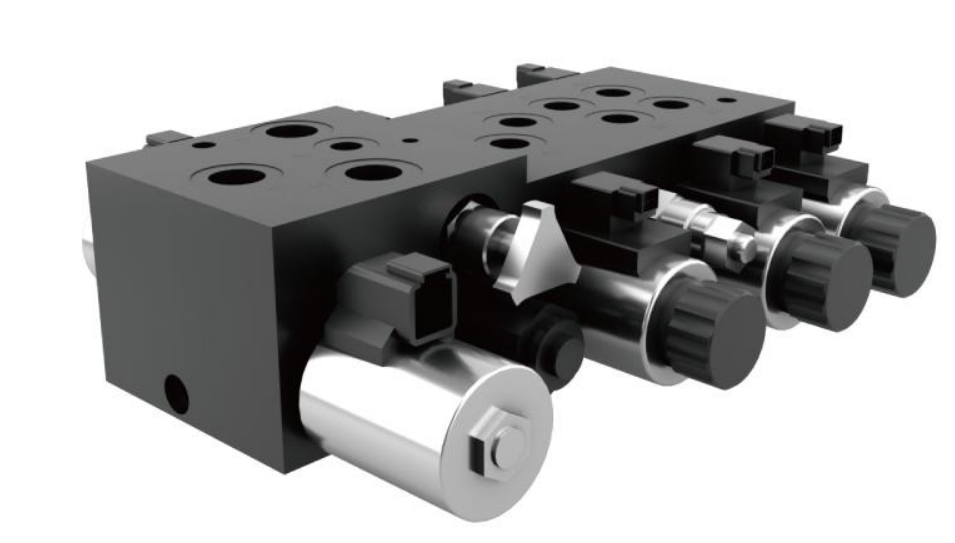

EYF*-15Multiway valve

Load-sensitive electro-hydraulic proportional multi-way valves

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Application Solutions

- Application solutions for hydraulic components for grader

- Application solutions for hydraulic components for truck-mounted cranes

- Application solutions for rock driller fluid components

- Harvester hydraulic components application solutions

- Internal combustion forklift application solutions

- Electric forklift application solutions

- Application scheme of hydraulic components for garbage compactor

- Application solutions for tractor hydraulic components

- Application solutions for wind power hydraulic components

- Application solutions for hydraulic components for injection molding machines

-

Service Support

-

News

-

Join Us

PRODUCT CENTER

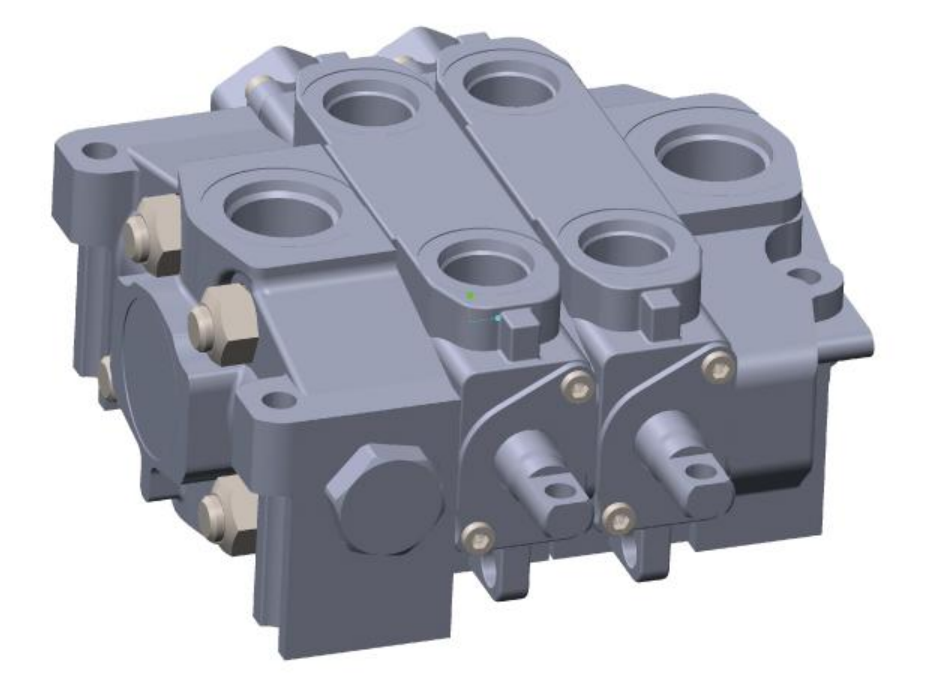

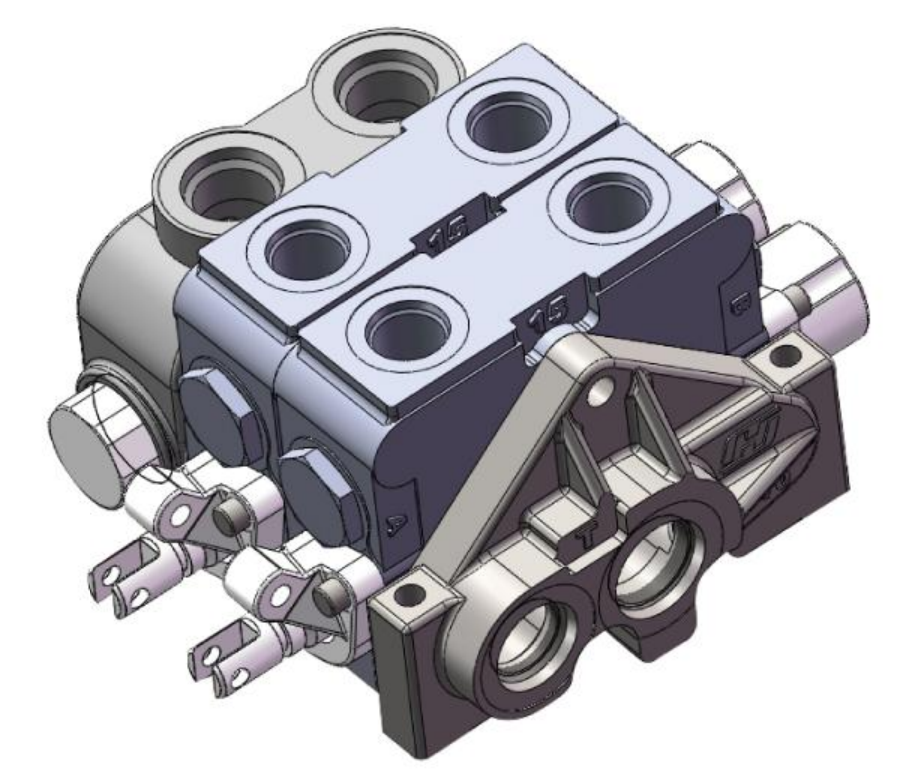

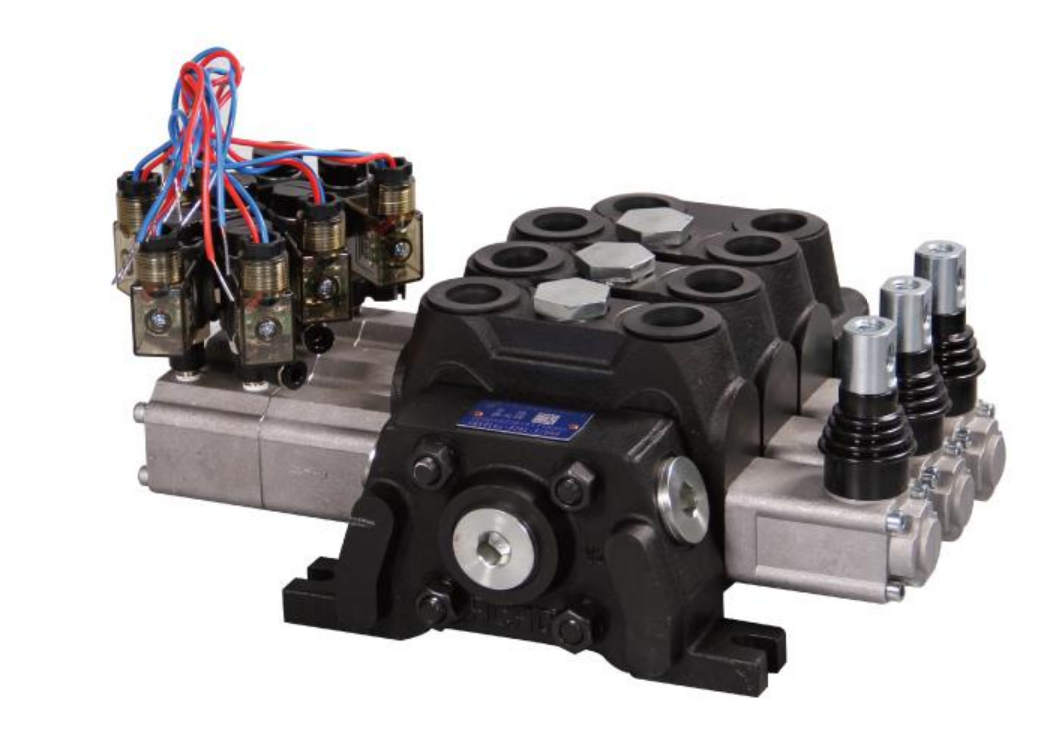

Multiple directional valveHCZTF-120 Multi-way valve

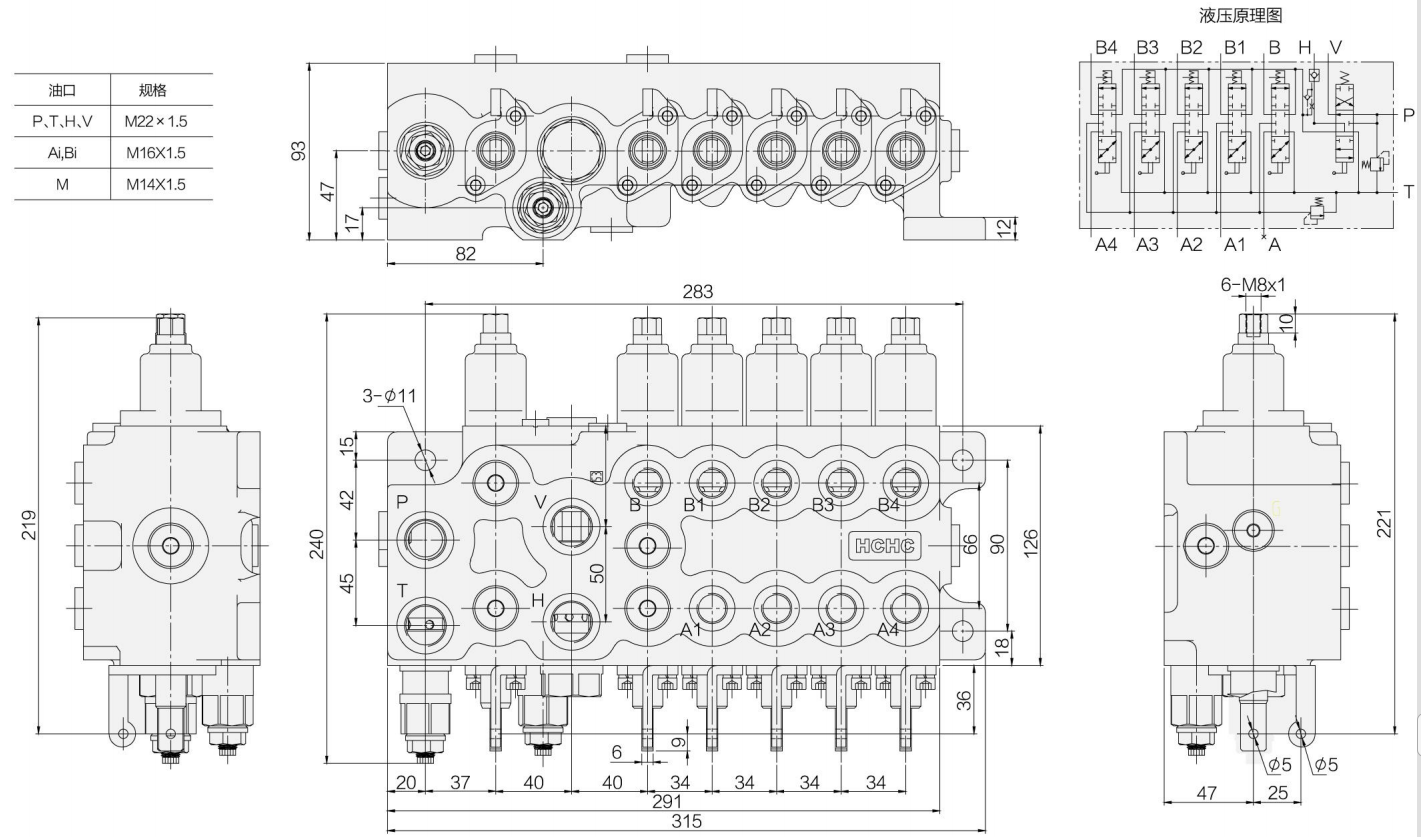

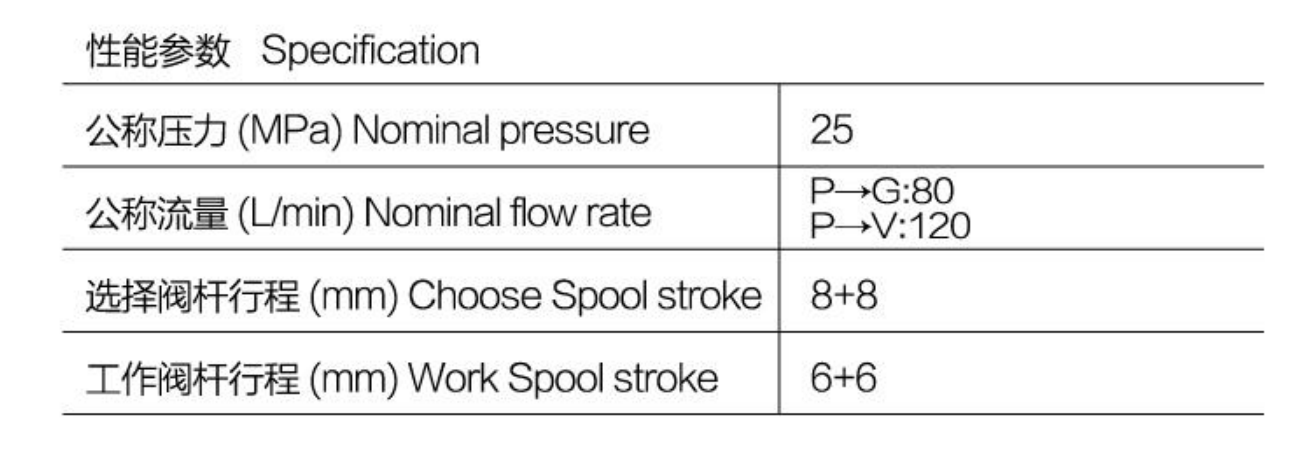

HCZTF-120 series multi-way valves are characterized by an inlet and return selector valve stem to control the on and off of the five oil lines in the working part, simplifying the structure, reducing the space occupied and the weight of the valve body. The selector valve stem is in spring reset mode, which is reset when the operator leaves his hand and cuts off the working part of the oil circuit to ensure safety; the working valve stem is in steel ball positioning mode, which is controlled separately, and the operator can still work normally when he leaves his hand, and a single or multiple cylinders can be selected to work at the same time; one cavity of the cylinder connects to the A and B ports, and the other cavity connects to the H port, and a total of ten groups of actuating elements can be controlled to provide diversified choices for the users. When the valve group is not working, all the flow from P to V is directly supplied to the next valve group, so the waste of energy is minimized.

HCZTF-G120L series multi-way valve has the features of complete functions, advanced performance, compact structure, safety and reliability, easy maintenance, etc. It is mainly applied in the chassis of many engineering machinery vehicles, such as automobile cranes, concrete pump trucks, aerial work trucks, and other machinery that needs a horizontal stable working platform. Can also be used in other lifting and transportation machinery, mining machinery, sanitation machinery in the hydraulic system.

Built-in hydraulic lock: hydraulic lock to ensure that the actuator leakage to meet user needs

Built-in one-way throttle valve: one-way throttle valve can reduce the hydraulic lock closing speed

Avoid negative pressure in the cylinder, contraction is not in place

Set the safety valve: control the maximum pressure of the valve group in the process of work

Setting overload valve: the overload valve ensures the overload protection and safety of the actuator in the working process

Valve Body Structure: Integral Structure

Neutral unloading;

Wider fine-tuning range independent of the number of simultaneously controlled directional valves, load pressure and flow rate;

由液压泵给LSOil is supplied to LS oil circuit by hydraulic pump, there is no danger of instantaneous load drop when getting pressure signal

The flow rate of each working port can be designed according to the user's requirements

low rate of each working port can be designed according to the user's requirements; compatible with the LS system: 1) different operation control methods can be selected for each working coupling on each valve; 2) the first coupling is equipped with a pressure reducing valve, which eliminates the need for an Independent first to oil source; Can be applied to variable pump system, quantitative pump system.

Drawings

Specification

Domestic market phone number:4008-123-910

+86-551-64391100

+86-551-64391122

Email:sale@hchc.cn

Global market phone number:+86-551-64396718

Email:export01@hchc.cn

After-sales support hotline:400-887-9946

Related links:https://ahhchc.en.alibaba.com

Related links:https://ahhchc.1688.com

Related links:https://ahhchc.en.made-in-china.com

-

ABOUT HCHC

-

Product Center

-

Application Solutions

- Application solutions for hydraulic components for grader

- Application solutions for hydraulic components for truck-mounted cranes

- Application solutions for rock driller fluid components

- Harvester hydraulic components application solutions

- Internal combustion forklift application solutions

- Electric forklift application solutions

- Application scheme of hydraulic components for garbage compactor

- Application solutions for tractor hydraulic components

- Application solutions for wind power hydraulic components

- Application solutions for hydraulic components for injection molding machines

-

Service Support

-

News

-

Join Us

Follow us on wechat

Copyright: Hefei Changyuan Hydraulic Co.,ltd [皖ICP备05012331号]

Anti-fake search

Anti-fake search