-

ABOUT HCHC

-

Product Center

Product

- HC internal gear pump

- CBRHA Gear pump

- CBRH Gear pump

- CBWS/F-D3 gear pump

- CBW/FB-E3 gear pump

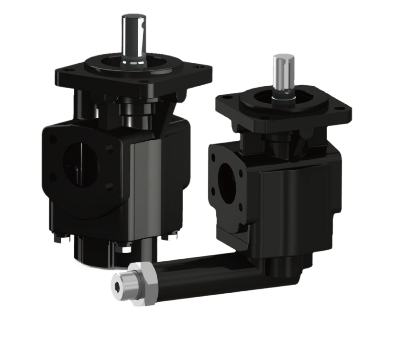

- CBXZ-C compound gear pump

- CBWKGY gear pump

- CBGT4 gear pump

- CBF-F5 gear pump

- CBGTGC Multi-gear oil pump

- CBVH Triple gear pump

- CBKP Triple gear pump

- CBKL-G/G double gear oil pump

- CBHYG-G/F double gear oil pump

- CBHY-G/F double gear oil pump

- CBV2/2 double gear oil pump

- CBGTFL double gear oil pump

- CBKP Double gear oil pump

- CBG2/2 Double gear oil pump

- CBGTBLT Double gear oil pump

- CBGTBLA2 Double gear oil pump

- CBTLZTD-F/F Double gear oil pump

- CBTLZTA-F/F Double gear oil pump

- CBGNL Double gear oil pump

- CBNL-F5/F5 Double gear oil pump

- CBHLB-F5/F5 Double gear oil pump

- CBHLD-F5/F5 Double gear oil pump

- CBQTF Double gear oil pump

- CBQT-*5/F4 Double gear oil pump

- CBQL-*5/F5 Double gear oil pump

- CBTL-*4/*4 Double gear oil pump

- CBWL-*3/*3 CBKL-G/G

- CBKP gear pump

- CBV gear pump

- CBGTG

- CBGTF2 Gear pump

- CBZTG3 Gear pump

- CBZTG2 Gear pump

- CBGTC2 gear pump

- CBGTB2 Gear pump

- CBZTC2 Gear pump

- CBTZTD Gear pump

- CBTZTA-F Gear pump

- CBGX Gear pump

- CBNZQ -F5 Gear pump

- CBN-F5 Gear pump

- CBWma-F,CBWmb-F Gear pump

- CBW-F2 Gear pump

- CBG2 Gear pump

- CBF-F6 Gear pump

- CBQ-*5 Gear pump

- CBHB-F5 gear pump

- CBH-*5 Gear pump

- CBF-*4 Gear pump

- CBWKA-F3 Gear pump

- CBHZA-F gear pump

- CBHZ-F Gear pump

- CBHE Gear pump

- CBHV Gear pump

- CBHV Gear pump(rear inlet and outlet)

- CBHC Gear pump

- CBKEC Gear pump

- CBTD-F4 Gear pump

- CBT-F4 Gear pump

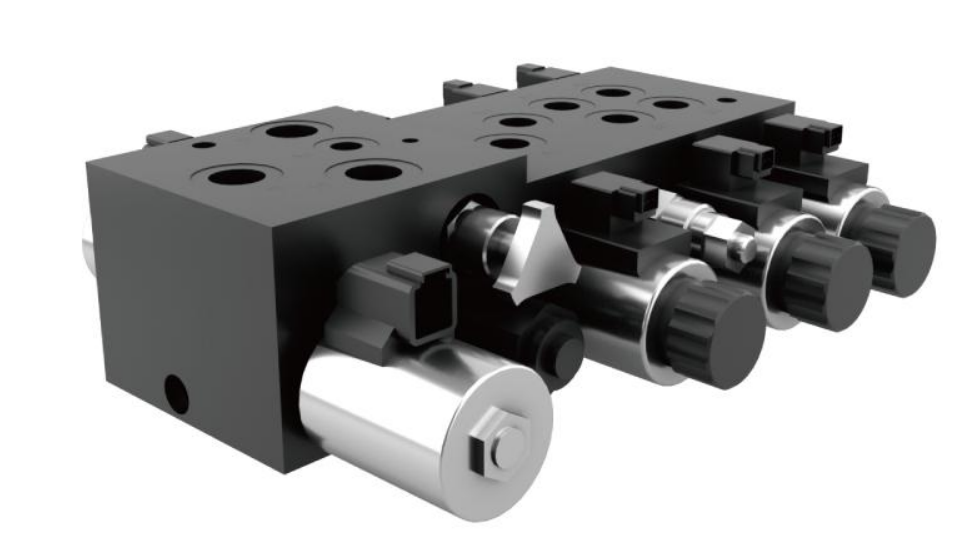

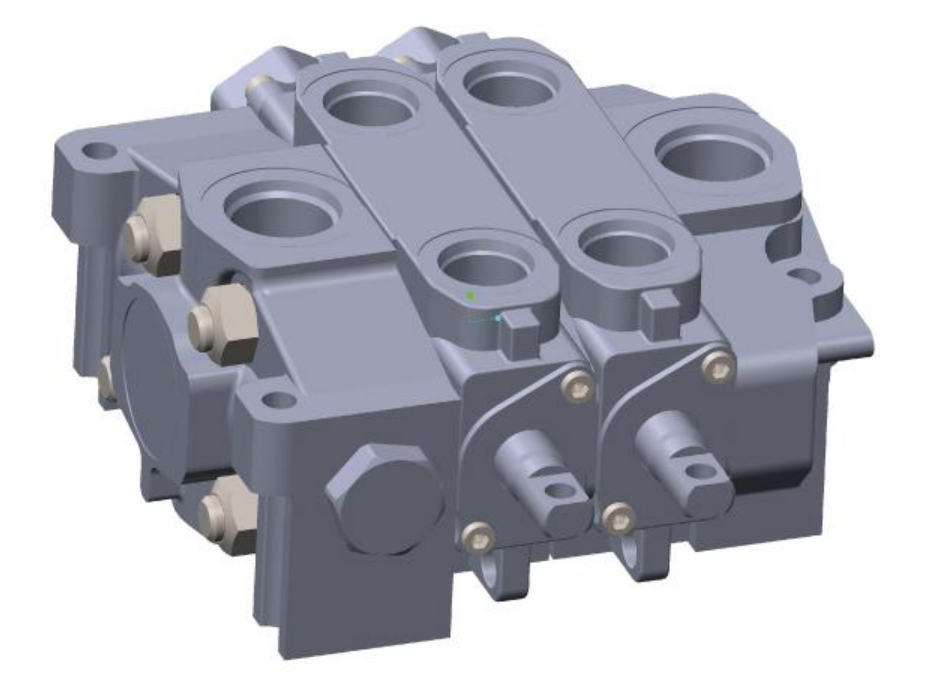

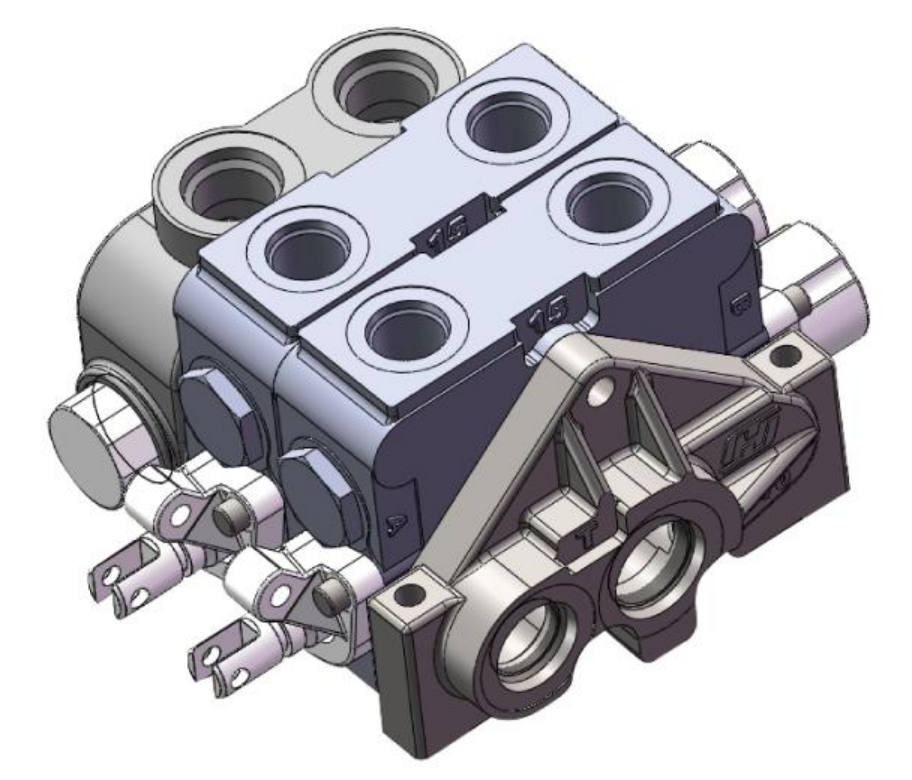

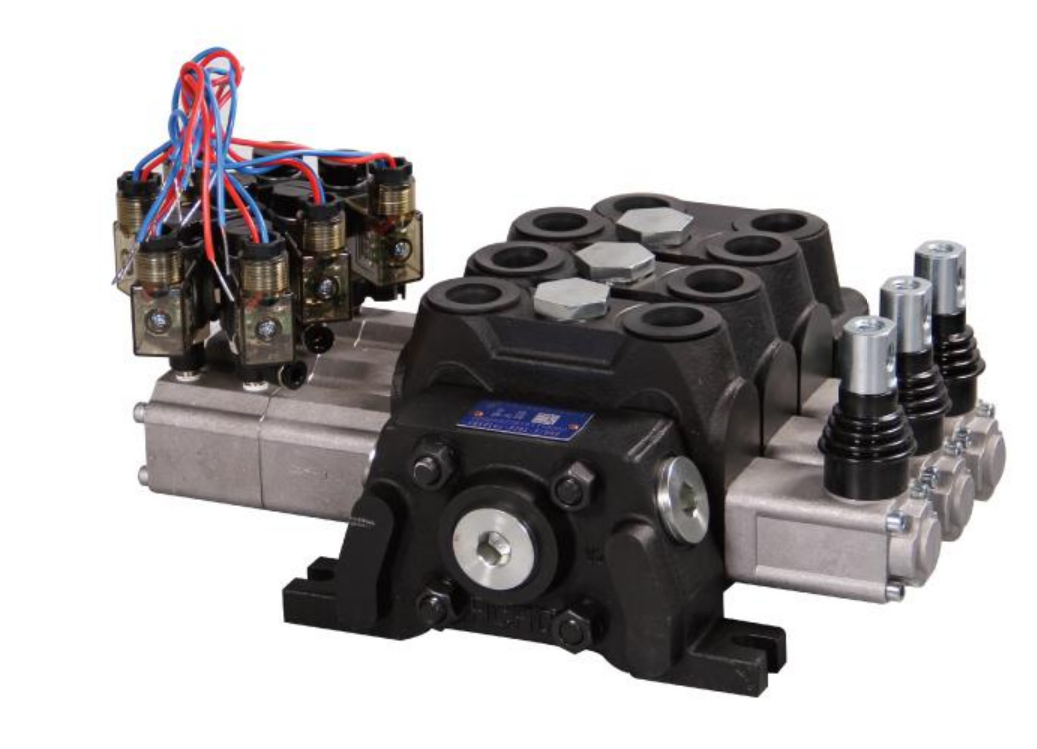

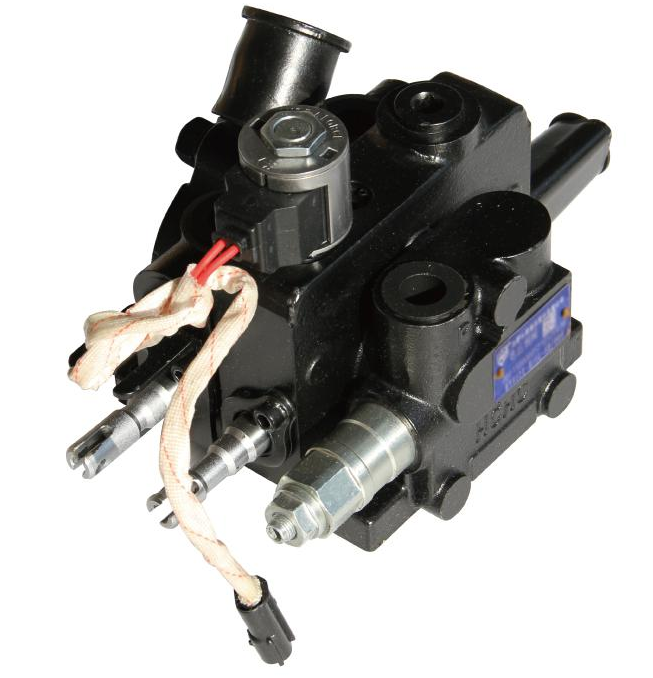

- EYF*-15Multiway valve

- HCZTF-120 Multi-way valve

- DYCDBF*-15Multiway valve

- DCFB-G60L-4 Solenoid Valve

- DCF*-50 Solenoid Valve

- XSFα* speed limiting valves

- 1WFL* Shunt valve

- SDV*-70 multi-way valves

- SDVA*-40 Multi-way valves

- SDV*-40

- SDV*-25

- ZDaG*-15 Multi-way valves

- ZDG*-15 Multi-way valves

- ZD*-10 Integral multi-way valves

- BDL*-40

- FP6G*-15

- EDL*-25 Multiway valve

- EDL*-20 Multi-way valves

- EDL*-15 Multi-way valve

- EDL*-10 Multi-way valves

- ZL*-20 Multi-way valves

- DLSG*-20 Multiway valve

- DLS*-20 Multi-way valves

- DLS*-15 Multiway valve

- DF28-15 Multiway valve

- DF*-15 Multi-way valves

- DL*-20 Multi-way valves

- DL*-15 Multi-way valves

- DYDLa*-20 Multi-way valve

- DYDLa*-15 Multi-way valve

- HCZF*-15

- OBV*/HXQ*

- YCDC*-20 Multiple directional valve

- YCDB*-20 Multiple directional valve

- CDB*-20 Multiple directional valve

- YCDC*-15

- YCDB*-15 Multiple directional valve

- DCDB*-15 Multiway valve

- CDB* -15 Multiway valve

-

EYF*-15Multiway valve

Load-sensitive electro-hydraulic proportional multi-way valves

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Application Solutions

- Application solutions for hydraulic components for grader

- Application solutions for hydraulic components for truck-mounted cranes

- Application solutions for rock driller fluid components

- Harvester hydraulic components application solutions

- Internal combustion forklift application solutions

- Electric forklift application solutions

- Application scheme of hydraulic components for garbage compactor

- Application solutions for tractor hydraulic components

- Application solutions for wind power hydraulic components

- Application solutions for hydraulic components for injection molding machines

-

Service Support

-

News

-

Join Us

SERVICE SUPPORT

Service Philosophy

Changyuan Hydraulics aims to create a competitive advantage for our customers and is committed to the research and application of hydraulic technology.

Focus on clients

-

Service Market

-

Collaboration with

customers -

Innovation is

essential -

Quality wins

-

Unity and

Collaboration -

Integrity and

Responsibility

Download

Knowledgea

- Hydraulic gear pump

- Hydraulic gear motor

- Hydraulic valve

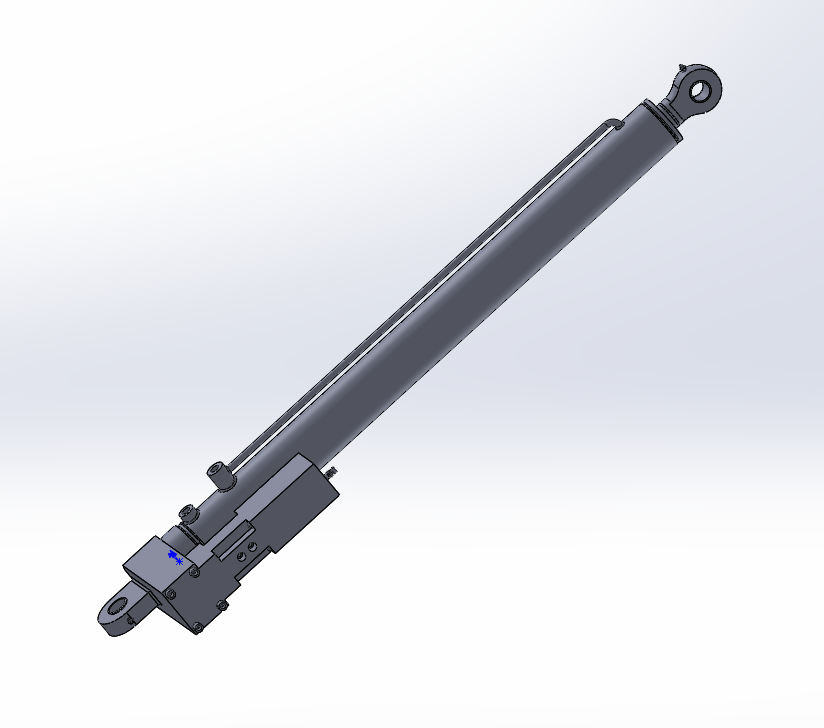

- Hydraulic Cylinder

- Working Media

Before starting the oil pump, you should carefully check the inlet and outlet, whether the direction of rotation is the same as the direction indicated on the label, and do not rotate in the opposite direction.

The flexible coupling should be used between the pump drive shaft and the output shaft of the prime mover, and its different shaft degree is not more than 0.1mm.

It should be ensured that the pump shaft is not subjected to radial force, axial force and bending moment. When installing the gear pump, the shaft should be introduced slowly, do not forcefully knock and axial collision, otherwise it will cause serious damage to the pump.

The suction height of the pump is not more than 0.5m.

The oil inlet connection flange must not be bumped. Combined surface and joint must be strictly sealed to prevent air leakage, otherwise it will cause noise, vibration, foam and other abnormal phenomena, and reduce the life of the gear pump.

The diameter of the suction pipe of the gear pump should ensure that the oil flow rate is less than 1.5m/s.

When installing the motor, the shaft should be introduced slowly and never forcibly knocked in.

The motor drive shaft and the power output shaft should be connected by flexible coupling, the different shaft degree is not more than 0.1mm.

The back pressure at the motor drain port must not be higher than 0.4MPa.

The inlet and outlet should be checked carefully before the motor is installed. Do not rotate in the opposite direction, and the direction of motor rotation should be the same as the direction indicated on the label.

Valve oil port bonding surface is strictly prohibited to bump, to ensure that the bonding surface, the joint is strictly sealed.

When installing the external manipulation mechanism, it should ensure that the slide valve is not subjected to lateral force, so that the movement of the slide valve is flexible and free of jamming.

Install each oil port correctly, and forbid dirt to enter.

The rated pressure of the safety valve in the hydraulic valve sold by our company has been adjusted before leaving the factory, so it is strictly forbidden to adjust it at will.

Hydraulic cylinder in the initial movement, should try to exclude the air in the cylinder to avoid crawling and abnormal noise and other phenomena.

Avoid scratching and bumping the piston rod to avoid seal failure and oil leakage.

The installation should pay attention to adjust the piston rod and cylinder barrel coaxially to avoid lateral force on the piston rod, resulting in piston rod bending, cylinder pulling, etc.

The hydraulic oil should be verified before the cylinder is used, and the use of harmful or contaminated oil is strictly prohibited.

The system pressure should be checked before use, and it is strictly prohibited to use the cylinder with super pressure.

It is recommended to use L-HM46 or similar viscosity hydraulic oil in summer and L-HM32 or similar viscosity hydraulic oil in winter.

Working oil temperature range -20℃~80℃.

System cleanliness directly affects the reliability of hydraulic components, before refueling, the oil tank, pipeline should be fully cleaned, the general pump suction side commonly used filter precision 100 purpose filter (its rated flow rate should not be less than twice the pump flow), the return line to connect the filter precision of not less than 25μm oil filter.

Domestic market phone number:4008-123-910

+86-551-64391100

+86-551-64391122

Email:sale@hchc.cn

Global market phone number:+86-551-64396718

Email:export01@hchc.cn

After-sales support hotline:400-887-9946

Related links:https://ahhchc.en.alibaba.com

Related links:https://ahhchc.1688.com

Related links:https://ahhchc.en.made-in-china.com

-

ABOUT HCHC

-

Product Center

-

Application Solutions

- Application solutions for hydraulic components for grader

- Application solutions for hydraulic components for truck-mounted cranes

- Application solutions for rock driller fluid components

- Harvester hydraulic components application solutions

- Internal combustion forklift application solutions

- Electric forklift application solutions

- Application scheme of hydraulic components for garbage compactor

- Application solutions for tractor hydraulic components

- Application solutions for wind power hydraulic components

- Application solutions for hydraulic components for injection molding machines

-

Service Support

-

News

-

Join Us

Follow us on wechat

Copyright: Hefei Changyuan Hydraulic Co.,ltd [皖ICP备05012331号]

Home

Home

Anti-fake search

Anti-fake search