-

ABOUT HCHC

-

Product Center

Product

- HC internal gear pump

- CBRHA Gear pump

- CBRH Gear pump

- CBWS/F-D3 gear pump

- CBW/FB-E3 gear pump

- CBXZ-C compound gear pump

- CBWKGY gear pump

- CBGT4 gear pump

- CBF-F5 gear pump

- CBGTGC Multi-gear oil pump

- CBVH Triple gear pump

- CBKP Triple gear pump

- CBKL-G/G double gear oil pump

- CBHYG-G/F double gear oil pump

- CBHY-G/F double gear oil pump

- CBV2/2 double gear oil pump

- CBGTFL double gear oil pump

- CBKP Double gear oil pump

- CBG2/2 Double gear oil pump

- CBGTBLT Double gear oil pump

- CBGTBLA2 Double gear oil pump

- CBTLZTD-F/F Double gear oil pump

- CBTLZTA-F/F Double gear oil pump

- CBGNL Double gear oil pump

- CBNL-F5/F5 Double gear oil pump

- CBHLB-F5/F5 Double gear oil pump

- CBHLD-F5/F5 Double gear oil pump

- CBQTF Double gear oil pump

- CBQT-*5/F4 Double gear oil pump

- CBQL-*5/F5 Double gear oil pump

- CBTL-*4/*4 Double gear oil pump

- CBWL-*3/*3 CBKL-G/G

- CBKP gear pump

- CBV gear pump

- CBGTG

- CBGTF2 Gear pump

- CBZTG3 Gear pump

- CBZTG2 Gear pump

- CBGTC2 gear pump

- CBGTB2 Gear pump

- CBZTC2 Gear pump

- CBTZTD Gear pump

- CBTZTA-F Gear pump

- CBGX Gear pump

- CBNZQ -F5 Gear pump

- CBN-F5 Gear pump

- CBWma-F,CBWmb-F Gear pump

- CBW-F2 Gear pump

- CBG2 Gear pump

- CBF-F6 Gear pump

- CBQ-*5 Gear pump

- CBHB-F5 gear pump

- CBH-*5 Gear pump

- CBF-*4 Gear pump

- CBWKA-F3 Gear pump

- CBHZA-F gear pump

- CBHZ-F Gear pump

- CBHE Gear pump

- CBHV Gear pump

- CBHV Gear pump(rear inlet and outlet)

- CBHC Gear pump

- CBKEC Gear pump

- CBTD-F4 Gear pump

- CBT-F4 Gear pump

- EYF*-15Multiway valve

- HCZTF-120 Multi-way valve

- DYCDBF*-15Multiway valve

- DCFB-G60L-4 Solenoid Valve

- DCF*-50 Solenoid Valve

- XSFα* speed limiting valves

- 1WFL* Shunt valve

- SDV*-70 multi-way valves

- SDVA*-40 Multi-way valves

- SDV*-40

- SDV*-25

- ZDaG*-15 Multi-way valves

- ZDG*-15 Multi-way valves

- ZD*-10 Integral multi-way valves

- BDL*-40

- FP6G*-15

- EDL*-25 Multiway valve

- EDL*-20 Multi-way valves

- EDL*-15 Multi-way valve

- EDL*-10 Multi-way valves

- ZL*-20 Multi-way valves

- DLSG*-20 Multiway valve

- DLS*-20 Multi-way valves

- DLS*-15 Multiway valve

- DF28-15 Multiway valve

- DF*-15 Multi-way valves

- DL*-20 Multi-way valves

- DL*-15 Multi-way valves

- DYDLa*-20 Multi-way valve

- DYDLa*-15 Multi-way valve

- HCZF*-15

- OBV*/HXQ*

- YCDC*-20 Multiple directional valve

- YCDB*-20 Multiple directional valve

- CDB*-20 Multiple directional valve

- YCDC*-15

- YCDB*-15 Multiple directional valve

- DCDB*-15 Multiway valve

- CDB* -15 Multiway valve

-

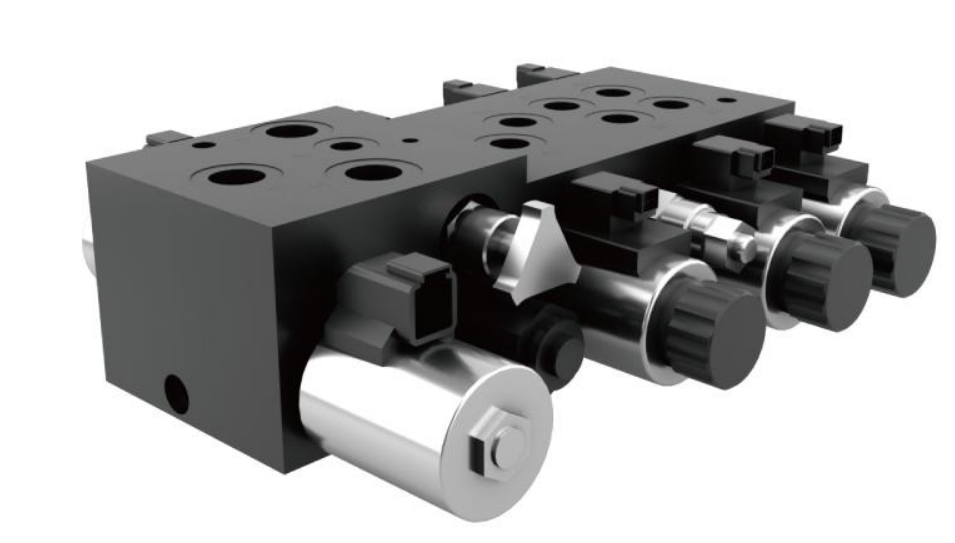

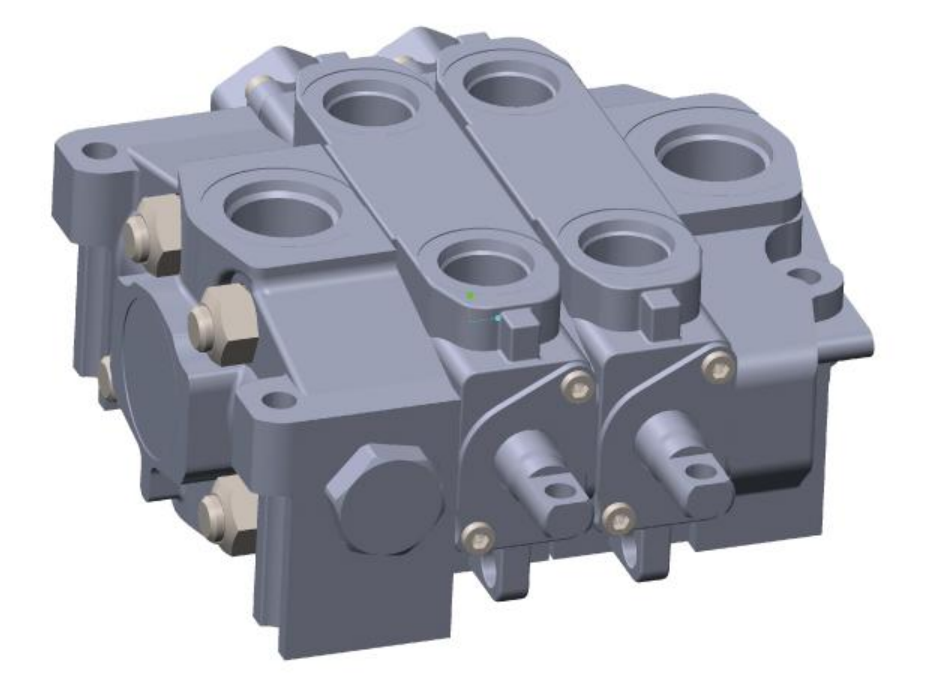

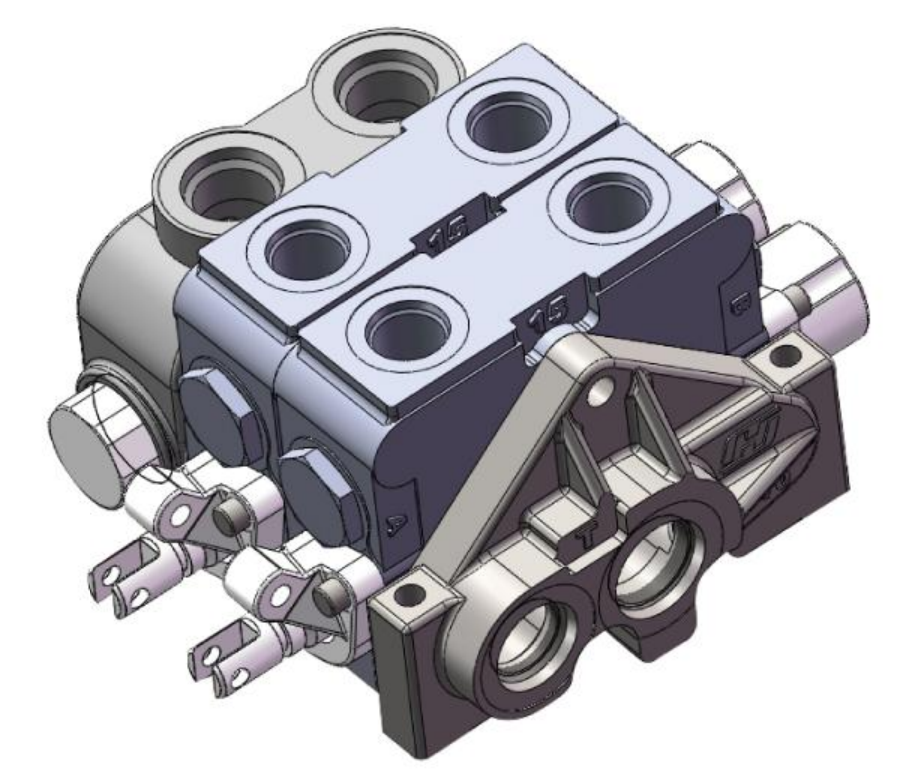

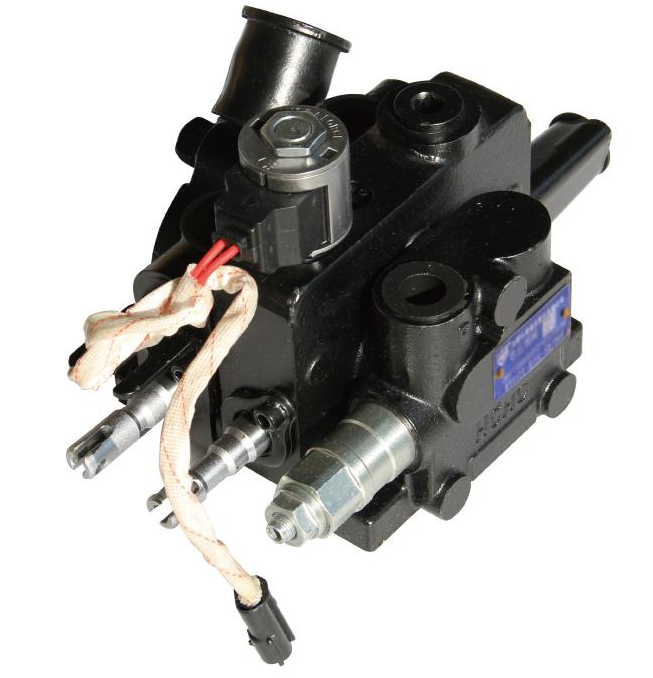

EYF*-15Multiway valve

Load-sensitive electro-hydraulic proportional multi-way valves

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Application Solutions

- Application solutions for hydraulic components for grader

- Application solutions for hydraulic components for truck-mounted cranes

- Application solutions for rock driller fluid components

- Harvester hydraulic components application solutions

- Internal combustion forklift application solutions

- Electric forklift application solutions

- Application scheme of hydraulic components for garbage compactor

- Application solutions for tractor hydraulic components

- Application solutions for wind power hydraulic components

- Application solutions for hydraulic components for injection molding machines

-

Service Support

-

News

-

Join Us

PRODUCT CENTER

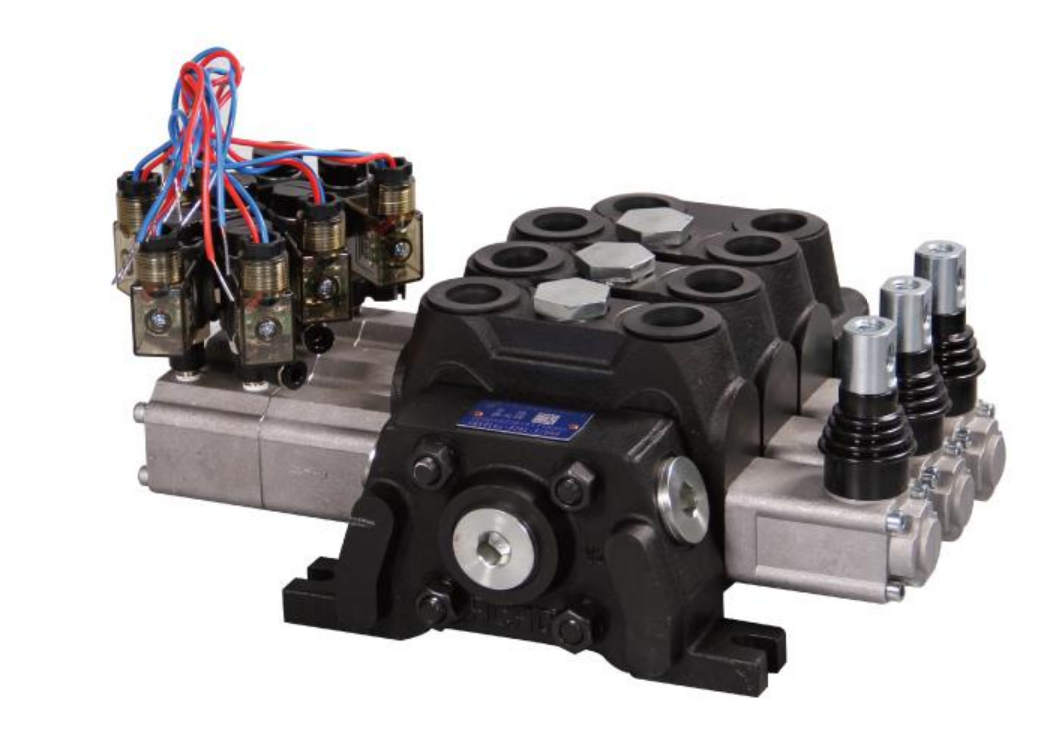

Multi-way directional valvesDYCDBF*-15Multiway valve

DYCDBF*-15 series of multi-way valves are mainly designed to improve the operating performance of forklift gantry, greatly reducing the impact of load changes on the cylinder moving speed, optimizing the micro-control of gantry action. This series integrates priority shunt valve and multi-way directional valve, so that the vehicle steering system and the cylinder working system share one multi-way valve, which reduces the complexity of the system structure and facilitates installation and maintenance. The valve is also equipped with a self-locking stem, which is used to prevent the forklift gantry from vibration that may be caused by the negative pressure inside the tilting cylinder, and locks the tilting cylinder when the engine is off, avoiding the false action that causes the forklift gantry to tilt forward and backward, which may cause a safety hazard.

DYCDBF*-15 series multi-way valves have the features of complete functions, advanced performance, compact structure, safety and reliability, easy maintenance, etc. They are mainly applied to small tonnage forklifts, small loaders and small excavators, and can also be used in other lifting and transporting machinery, mining machinery, and sanitation machinery in the hydraulic system.

OPS function: The lifting linkage can be equipped with optional OPS function according to the demand, avoiding misoperation causing the gantry to fall and further guaranteeing the safety of the work site.

Built-in Priority Valve: The oil inlet part is equipped with a priority valve, which provides flow for the steering system on a priority basis, and does not provide steering flow when it is not steering.

Additional valves: at both ends of the reversing body, different pressure overload valves or replenishment valves can be added at different oil ports according to customers' needs.

Built-in check valves: Each reversing body has built-in check valves to prevent backflow of oil. Setting valve stem self-locking: Prevent vibration of forklift gantry due to negative pressure inside the tilting cylinder and lock the tilting cylinder when the engine is turned off to avoid tilting of forklift gantry back and forth by mistake, which may cause hidden safety hazards.

Setting double safety valves: the main safety valve controls the system pressure, and the diversion safety valve ensures the normal working pressure of the steering system.

Additional valves: at both ends of the commutator, overload valves or make-up valves can be added according to requirements

Valve body structure: piece structure, any combination within 1~10 links

Stem center function: A, Z, O, Y, etc.

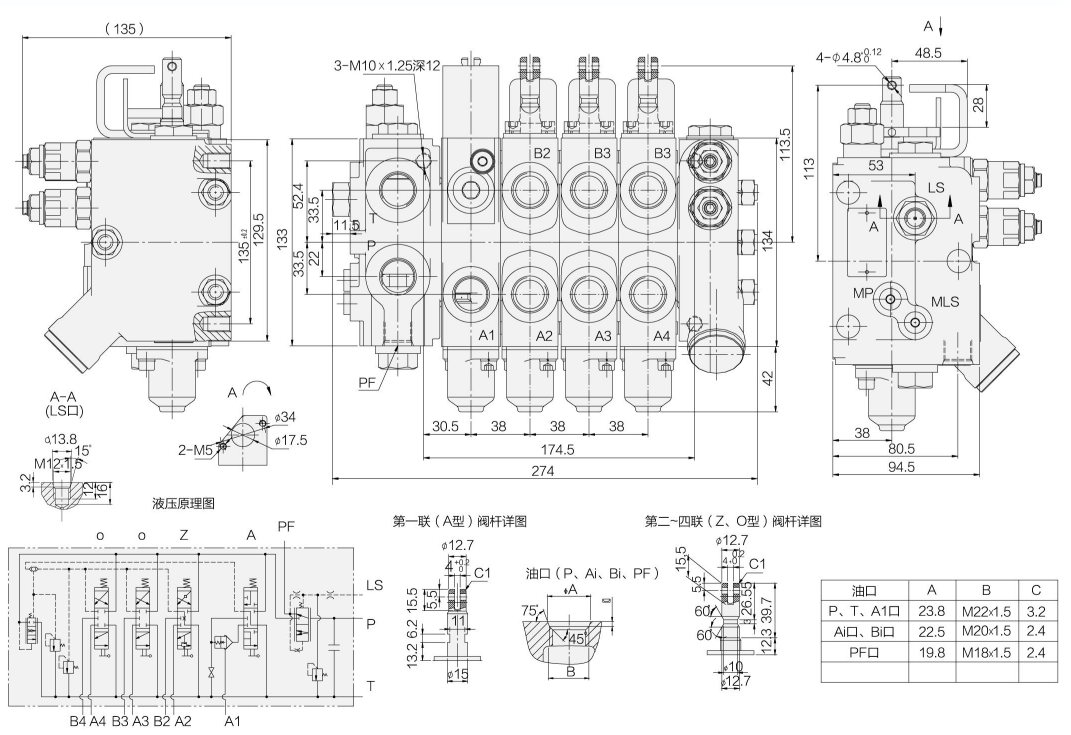

Drawings

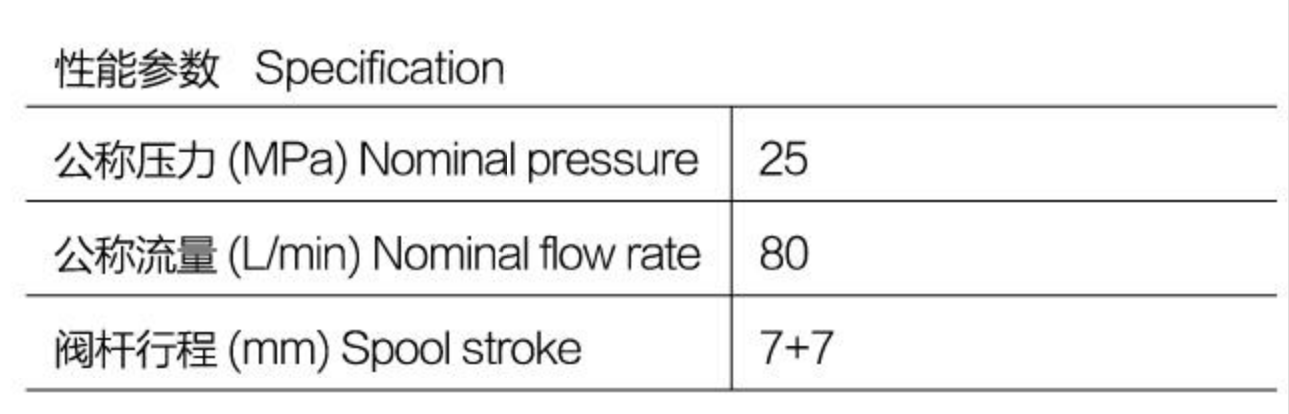

Specification

Domestic market phone number:4008-123-910

+86-551-64391100

+86-551-64391122

Email:sale@hchc.cn

Global market phone number:+86-551-64396718

Email:export01@hchc.cn

After-sales support hotline:400-887-9946

Related links:https://ahhchc.en.alibaba.com

Related links:https://ahhchc.1688.com

Related links:https://ahhchc.en.made-in-china.com

-

ABOUT HCHC

-

Product Center

-

Application Solutions

- Application solutions for hydraulic components for grader

- Application solutions for hydraulic components for truck-mounted cranes

- Application solutions for rock driller fluid components

- Harvester hydraulic components application solutions

- Internal combustion forklift application solutions

- Electric forklift application solutions

- Application scheme of hydraulic components for garbage compactor

- Application solutions for tractor hydraulic components

- Application solutions for wind power hydraulic components

- Application solutions for hydraulic components for injection molding machines

-

Service Support

-

News

-

Join Us

Follow us on wechat

Copyright: Hefei Changyuan Hydraulic Co.,ltd [皖ICP备05012331号]

Anti-fake search

Anti-fake search